Powder Packaging

Powdered product packages for powder filling need to be both durable and beautiful. Depending on their contents, they may also require FDA compliance, spoilage prevention, BPA content assessment and much more. It’s a lot to consider, and you can’t make critical packaging decisions alone. So whether you’re an electrolyte company selling your very first product or an industrial powder product manufacturer reevaluating your packing needs, we’re here to help.

Powder Packaging Equipment for Any Industry and Application

Not all powder products are alike. That means the packaging requirements for your powder filling products are unique, too. Here's more about packaging powders and our powder filling machine.

FDA packaging powders uses:

Industrial, CPG, and other powder bag uses:

Industrial Agriculture

CPG

Powder Packing for Baking and Cooking

Flour, Sugar, Salt, Spices, Cake Mixes and Pancake Mixes

Spoilage prevention and shelf life are top priorities here. Whether for the home chef or wholesale distribution, it comes down to quality materials and reliable seals and closures. Skip ahead to Preventing Spoilage and Poor Shelf Life to read more about this.

Electrolytes and Drink Mixes

From athletes to weekend warriors, your core customers have portability and pourability on their minds. The right configuration may mean the difference between a sale and a lost opportunity. Read on to see how Our Powder Packaging Experts Help Find Your Perfect Configuration.

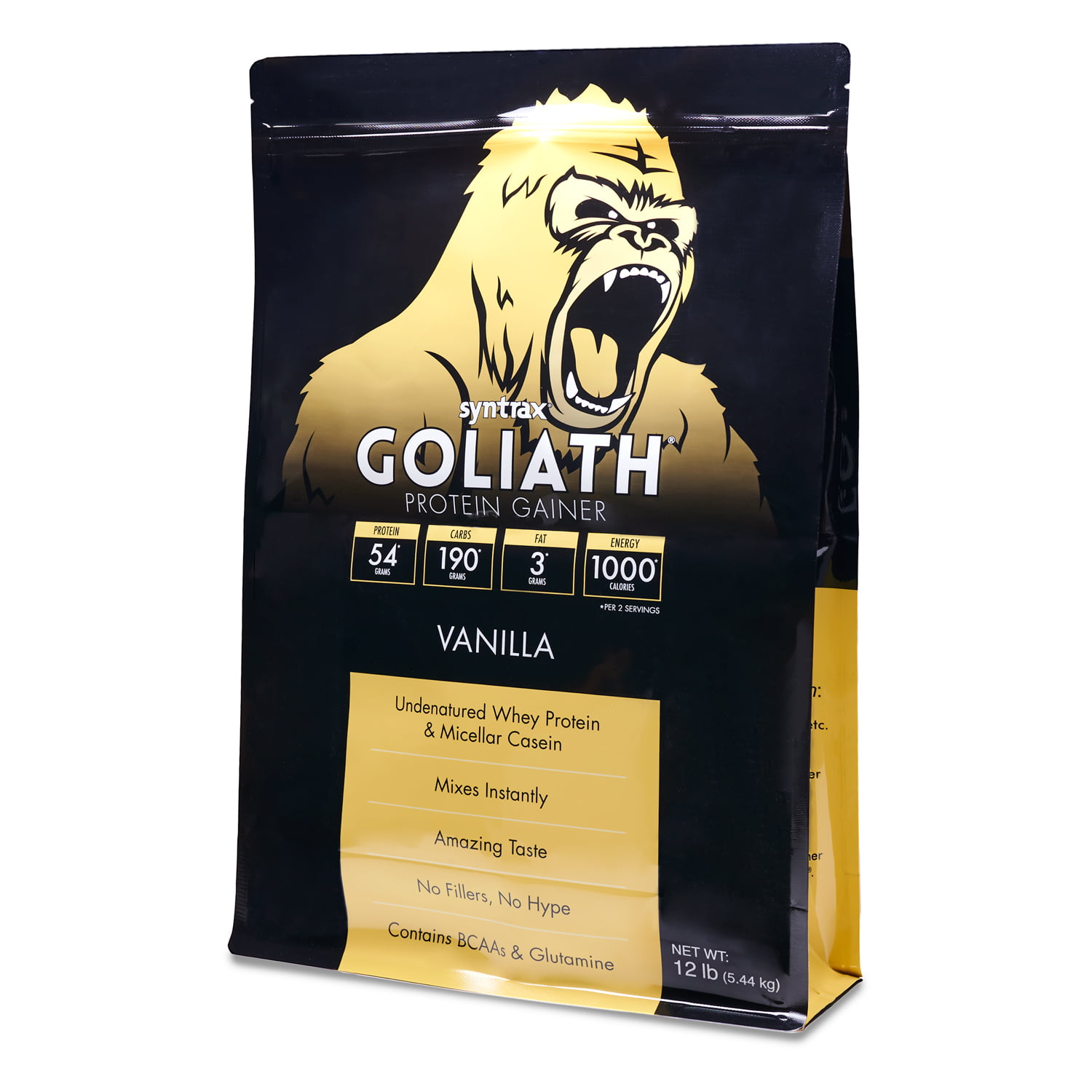

Supplements and Protein Powders

Protein powders and milk powder packaging is its own world. Beyond simple shelf life considerations, there’s also concerns over bag leakage potency retention and reclosability to consider. You’ll find more about how CarePac handles these concerns in our section on Preventing Spoilage and Poor Shelf Life.

Industrial Powders

Product safety during transit is critical for any powdered product manufacturer. But can you imagine an entire truckload of 50-pound fertilizer bags suffering blow-outs? We have — and that’s why we’re Combating Bag Blow-Outs.

No matter your industry, we have a custom packaging solution for your powdered product.

Powdered Product

Packaging Safety Features

Top packaging challenges for powdered product manufacturers like you include:

Material compliance and composition

- Blow-outs

- Spoilage

- Poor shelf life

- Eco-friendliness

Our custom flexible barrier packaging combats all those concerns and more.

Compliant Packaging

Compliance and customer safety are non-negotiable. When you work with CarePac, the solutions are easy.

All of our packaging options and equipment are compliant. Here is more information about our powder packaging machinery and powder packaging equipment.

FDA approved

BPA free

Kosher

Sulfur free

TSE free

Phthalate free

Worried about product reactions with packing materials?

With flexible barrier packaging, the innermost layer is a polyethylene sealant — meaning it won’t react with your product.

Combating Bag Blow-Outs and Leakage

Blow-outs happen when a bag’s seal bursts, usually in transit. This is a common issue with multi-serving powder packages. But while we can’t completely avoid blow-outs, we can reduce their frequency.

Firstly, we can reinforce the pouches. Extra-strength layers of specific materials, like nylon, add to the bag’s overall burst strength. Consider our CareSilver-PVNP and CareFoil-PANP films for flexible barrier packaging.

CareSilver-PVNP

CareFoil-PANP

We can also increase the film structure’s sealant layer thickness. We typically suggest 6 mil or 7 mil total thickness for powder packaging materials.

You can also reduce blow-outs by controlling how much product you put in the pouch, how much air is left, and how bags are protected during transit. Logistic chain analysis identifies the point(s) where rough handling or drops occur during transit.

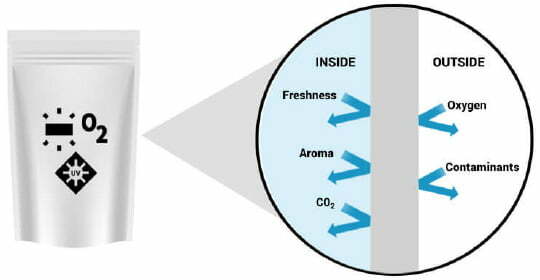

Preventing Spoilage and Poor Shelf Life

Many of the same steps used to combat blow-outs can prevent spoilage and prolong shelf life. Our flexible barrier packaging is made up of pliable plastics, aluminum, paper and coatings specified to your product, keeping it safe and fresh.

Don’t forget reclosable features. Residual powder particles can prevent consumers from getting a proper reseal after each use, leaving products exposed to oxidation, moisture and light.

We offer anti-fouling zipper pouches designed specifically for powdered packaging, so customers can use and reclose your product without fear of spoilage. This feature is ideal for bagging food powder products like coffee and protein powders as well as household items like fertilizer.

Eco-Friendly Compostable Packaging Options

Some 85% of consumers around the world factor sustainability into their purchasing decisions. So how can your powdered packaging fit into an eco-friendly framework?

We offer an assortment of pouches, mailers and tubing made from recyclable materials and compostable plastics such as monolayer PLA, transparent cellulose and PE+D2W.

Our Powder Packaging Experts Find Your Perfect Configuration

Our configurations accommodate all product types and fill equipment.

Here are the ones best suited to powder products and food.

Pouches

Stand up pouches (SUPs) are perfect for high-volume products like protein powders and powdered milk. 2 seal pouches are a great choice for those transitioning from stock to custom pouches. 3 seal pouches are a budget-friendly alternative to the stand up pou[PS1] ch. Box bottom pouches are ideal for bagging coffee and other similar powders, while side gusset pouches are a box bottom alternative often used for coffee as well.

[PS1]I deleted tamer evident.

Packets & Sachets

Single-serving products need the same protection from light, moisture and oxygen as their larger counterparts. Find durable packets and sachets perfectly sized for your electrolytes, salts, seasonings and other single-serving needs.

Stick Packs

Often seen in the energy and nutrition space, stick packs rival any other configuration for ease of use and portability. They’re perfect for water-soluble solutions that your customers use on the go. Electrolyte teams, we’re looking at you!

Custom Packaging Construction, Sizes and Printing

When we say “custom packaging,” we mean it.

Here are all the ways you can customize your powdered product packaging.

Contact us to discuss our services today.

Digital and Plate Printing Directly on Your Package

The bags look exactly the same. Unless you are in the bag business you cannot tell the difference. However, printing is different.

Digital Printing

Digital printing is a lot like the inkjet printer in your home or office. It leverages CMYK colors and can easily transition, printing multiple pouch images and SKUs at once.

Plate Printing

Plate printing uses metal cylinders that have imprints of your design, to be essentially “stamped” onto the bag. Every unique color for each side of your package needs its own plate.

So how to choose?

Cost: While there are no setup costs for digital printing, you pay a fee to create the plates for plate printing. However, plate printing offers a significantly lower cost per unit. Just look at this example of 42% savings with plate printing:

Relative cost of a large re-enforced Powder pouch

DIGITALLY PRINTED

Simple, fast and effective great for start-ups.

PLATE PRINTED

Lowest Per-unit cost when you're ready to scale.

Quantity: With our low minimums, you can place a starter order of just 1,000 bags. Digital is a great choice for that because the plate fee wouldn’t be offset by such a low quantity, meaning plate printing would be more expensive in that case. Ordering more than 1,000 bags? Go with plate printing.

High-End Finishes: Plate printing gives you access to high end finishes and effects that are not available with digital printing. Such as Spot Gloss / Spot Matte, Matte Varnish (instead of laminations) and true PMS Pantone Ink colors.

Color Fidelity: Digital CMYK printing can produce significant color variations. When it comes to your packaging, color variations aren’t worth the risk of brand confusion. Plate printing uses Pantone color numbers, so your brand colors are consistent.

Custom Packaging Sizes

Our smallest package size is a single-use sachet, great for single-serving salts, spices, electrolytes and more. Larger sizes are customizable down to precise .124" increments, creating a perfect fit for every product.

Accurate sizing is critical when you consider the bulk density of your product and whether it’s a free-flow or non-free-flow powder.

- Free-flow powders don’t condense or compact on pressure; they dispense easily when poured. Think about coffee, table salt or sugar.

- Non-free-flow powders usually have a higher moisture content; particles may stick together or compress when compacted. Protein powders, some (but not all) fertilizers and brown sugar are examples of non-free-flow powders.

Using the same size of package for equal weights of free-flow and non-free-flow powders usually isn’t the best choice. Non-free-flow powders are typically heavier by volume, leaving more room in the bag.

Because of this, custom sizing gets you the best value for each of your powder types.

Free-flow and non-free-flow powders also impact which filler you’ll use. More on that in the next section.

Customized for Your Fill Equipment

CarePac supplies roll stock for use with vertical form fill. Powdered products lend themselves well to vertical form fill machines as they can be precisely metered with a hopper filler or other type of machine. Form fill seal (FFS) pouches and bags require roll stock to meet specific web widths and roll lengths. Our fully custom roll stock can help ensure your form fill machine works at top efficiency.

Skip the Stock: Affordable and Streamlined Processes for Your Customer Packaging Needs

Package design might be one of the last things on your mind as you grow your business. So if you’re using stock packaging right now, we aren’t judging!

But hear us out: an investment in custom packaging is an investment in the growth of your business. You can build brand trust and loyalty while boosting your sales with an efficient and affordable custom design.

CarePac works with US-based manufacturers, allowing us to provide controlled lead times and low shipping costs. We offer several production processes to fit your deadline and budget:

- Express: Less lead time, higher investment

- Standard: Average lead time, average investment

- Economy: More lead time, lower investment

Altering your packaging process is stressful enough without unexpected pitfalls! Other providers may manufacture and ship overseas, resulting in unexpected customs delays, inflated shipping costs and import taxes.

It's normal to have lots of questions, buying custom packaging isn't like buying business cards, the bags need to both look great and perform well. Our customer service line connects you with a straight-talking industry expert in the United States right away. We’re here to answer all your questions and we have the right questions for you, too! This ensures you don’t waste time and money on orders that don’t meet your needs.

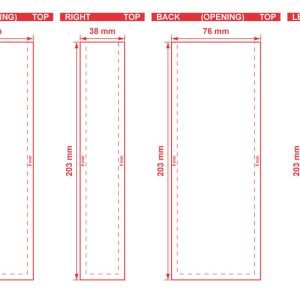

Side Gusset Bag 3x8x1.5 Dieline

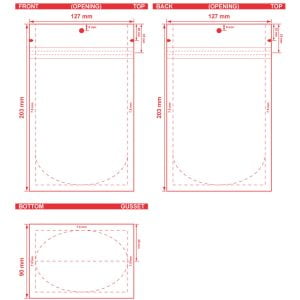

Side Gusset Bag 3x8x1.5 Dieline  Custom Printed Stand Up Pouch 5x8x3.5 Dieline

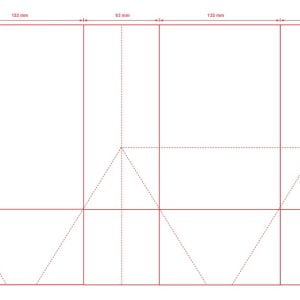

Custom Printed Stand Up Pouch 5x8x3.5 Dieline  Shopping Bag Dieline 5.25x3.25x8

Shopping Bag Dieline 5.25x3.25x8