No products in the cart.

Data Sheets

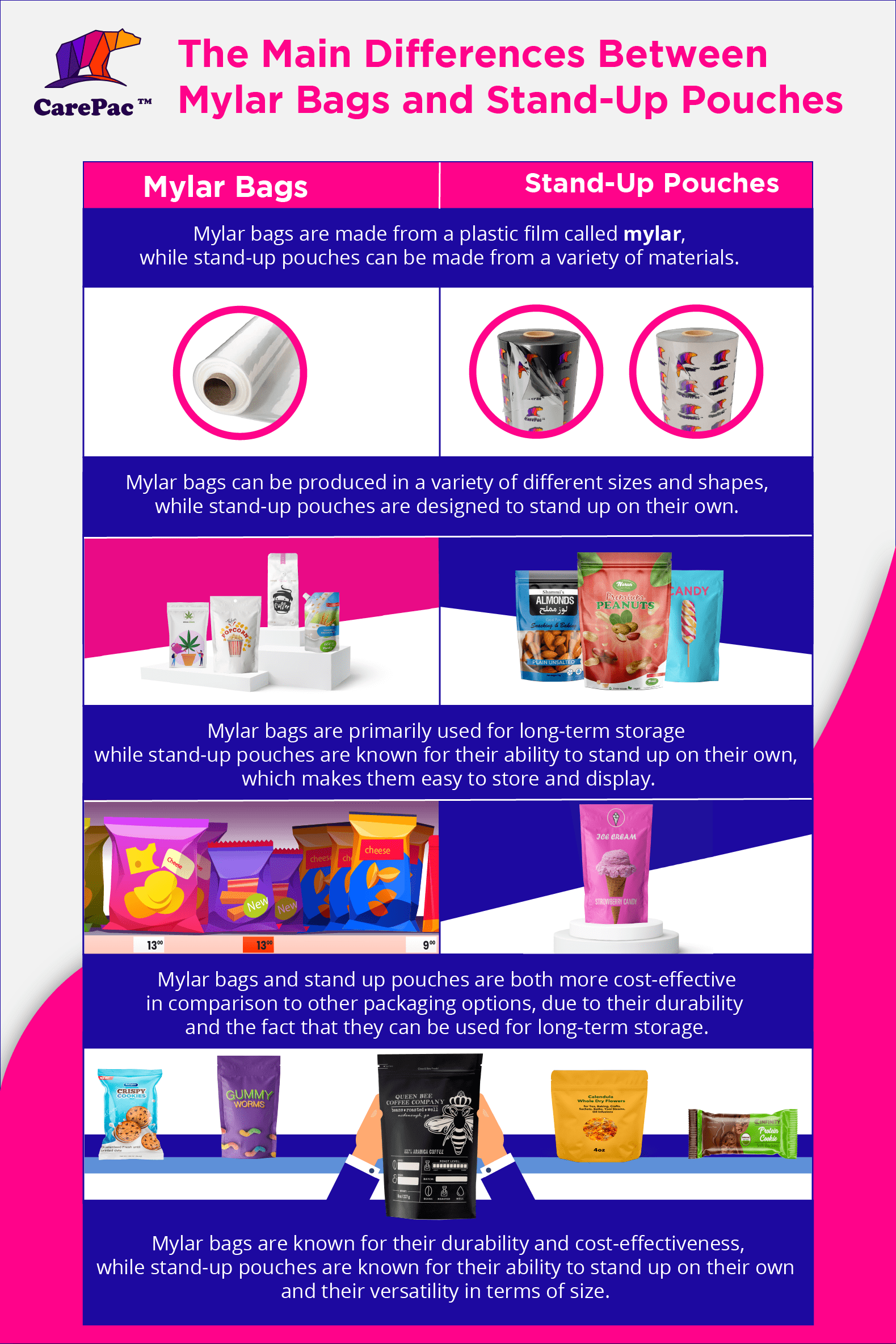

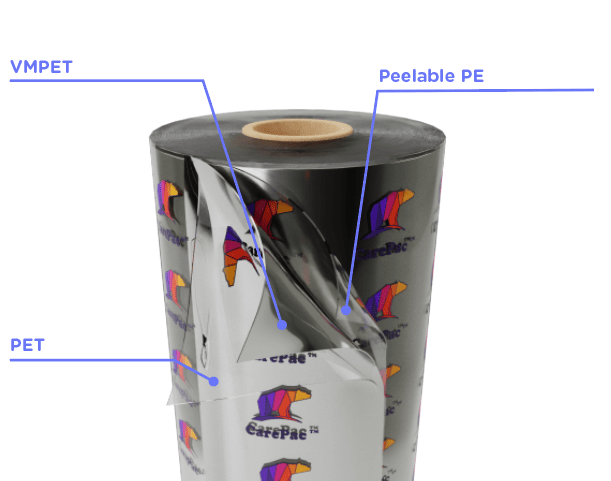

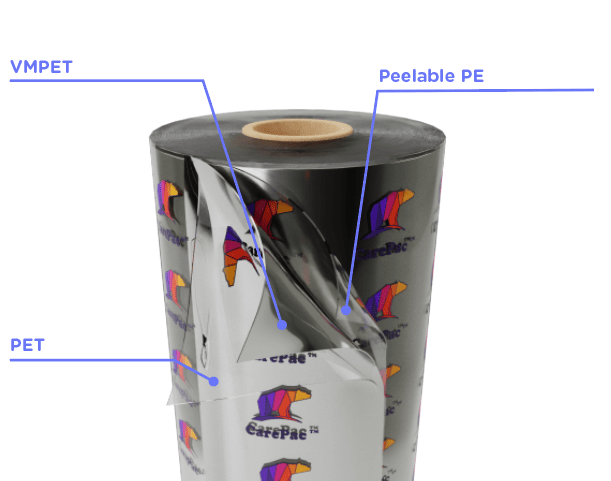

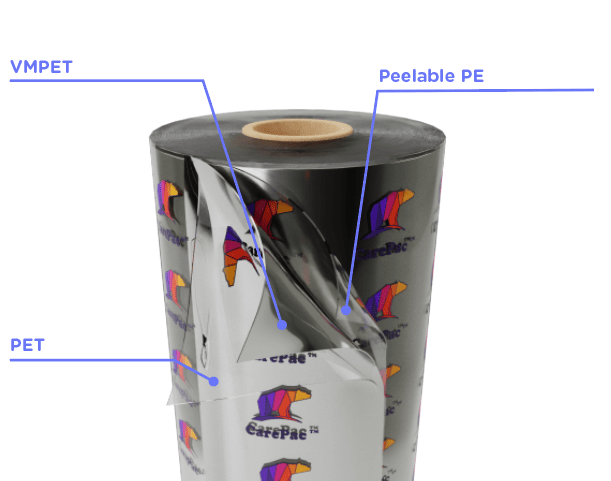

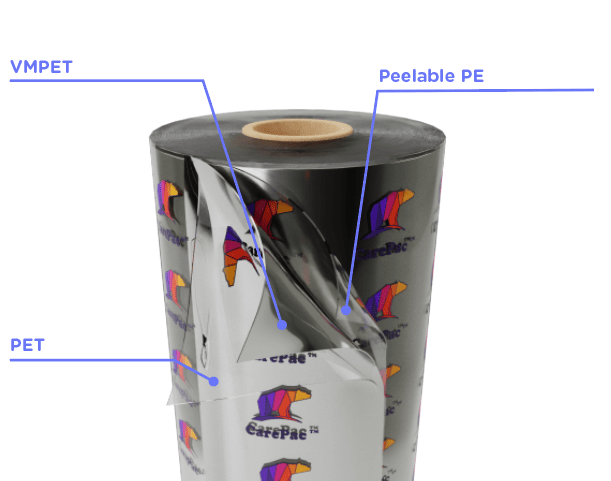

CareSilver-PVEASY

CareSilver-PVEASY

Overview

This FDA approved film does not stretch due to the orientation of the layers during the lamination process. Great for Food and industrial uses, the film.

CareSilver-PVP is a PET/VMPET/PE barrier lamination film that serves as a great base for printed bags, and provides a quality general use barrier to protect the contents from oxidation, moisture, and premature spoilage. Combine with EASY peel material usually use for face care, samples etc. , that delivers effortless, consistent opening for a frustration-free, accessible consumer experience.

Note: The performance of any film will be influenced by a number of factors and testing must always be performed to ensure the film meets the use.

Relative Performance Indications

Oxygen Barrier

Moisture Barrier

Light Barrier

STrength

Heat Resistance

Freezer Storage

Material Data

Here are some of the common indicated properties for this film.

Film Property | Sample Data |

|---|---|

Available Thicknesses | 2mil - 8mil |

Sample Data Thickness | 4mil |

MVTR | <1.5 JIS Z 0208 |

OTR | <0.9 JIS Z 1707 |

Elongation at Break | MD > 55 TD > 50 |

Bond Strength | PET/VMPET >400g/15mm VMPET/PE >400g/15mm |

All values indicated regarding film properties or characteristics, were provided by our film supplier and are given as an indication and should be considered as average indicative values. This document is based on our film supplier statements and / or independent lab testing, data from multiple tests, or different film suppliers of the same film family may be combined in the above table. While unexpected, it is possible that the validity of the statements could change without notice.

Environmental Impact

This material is a multi-layer laminated plastic and will typically fall into the check-locally, or store drop off category.

Property | Sample Data |

|---|---|

Recyclable | Multi-Layer Check Locally |

PCR Option Available | No |

At Home Compostable | No |

Commercial / Industrial Compostable | No |

Recyclability and composability varies by jurisdiction. Composability claims are limited by law, and vary by jurisdiction, consult a qualified professional in your state.

Compliance

Compliance is important, and here are CarePac we can support your compliance needs with extensive film supplier and lab testing data.

BPA FREE

FDA Food Approved

PROP 65

Compliance information above is derived from lab testing, or film supplier statements. Independent verification is advised, and Lot specific testing available.

Property | Sample Data |

|---|---|

CEPE/EuPIA | Manufactured in accordance with |

Cal. H&S (25214.16) | Compliant |

PFAS - perfluoroalkyl and polyfluoroalkyl § 37-0209, RCW 70A.222.070 | Does not knowingly add |

Prop 65 (OEHHA) | Does not contain listed substances |

SR 817.023.021 | Not in excess of overall or specific migration |

EU directive 10/2011/ED | Compliant |

EU directive 1935/2004 | Compliant |

FDA 21 CFR 73 | Compliant |

Cal. H&S (25214.16) | Compliant |

RoHS Directive 2011/65/EU | PASS |

Related Materials

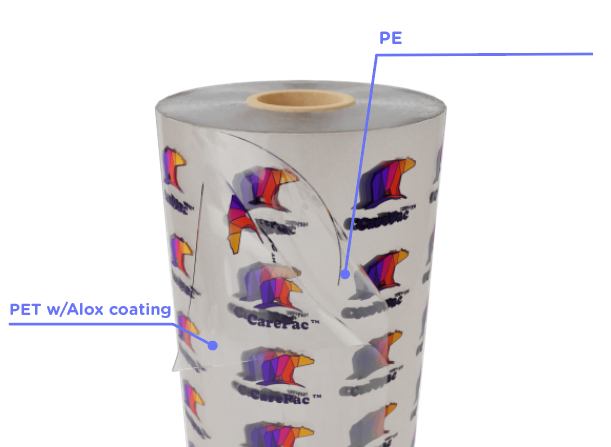

CareClear-PEASY

This film is designed to provide very good moisture and oxygen barrier potential in a transparent film. The ALOX coating enhances the barrier of the PET film.