No products in the cart.

Food Industry Packaging, Other Packaging Topics

Tin Tie Machines

Introducing CarePac’s Tin Tie Machine for Coffee Packaging

Why Tin Tie Closures Are Essential in Coffee Packaging

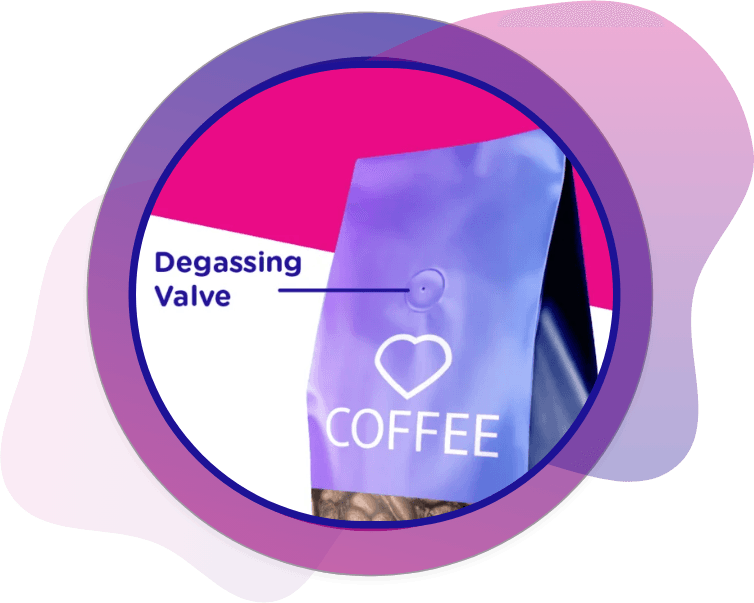

Ground coffee and coffee beans are just as delicate as most foods. They need to be stored at the appropriate temperature and exposure to oxygen and moisture can impact its aroma and taste. While instructing customers to store their coffee in a cool, dry place is a great place to start, the best way to ensure your customers enjoy fresh and aromatic coffee beans is to use resealable coffee bags, and ideally not bags that use clear tape. This is where tin tie reclosures enter the conversation.

If your existing coffee packaging isn't resealable, your best option is to add high-quality tin-ties to your coffee bags. Tin tie applicators will protect the coffee inside as intended without having to introduce extra stress or equipment into your customer's life. Fortunately, CarePac's tin tie machines can take the guesswork out of the entire process.

Technical Overview of CarePac’s Tin Tie Applicator Machine

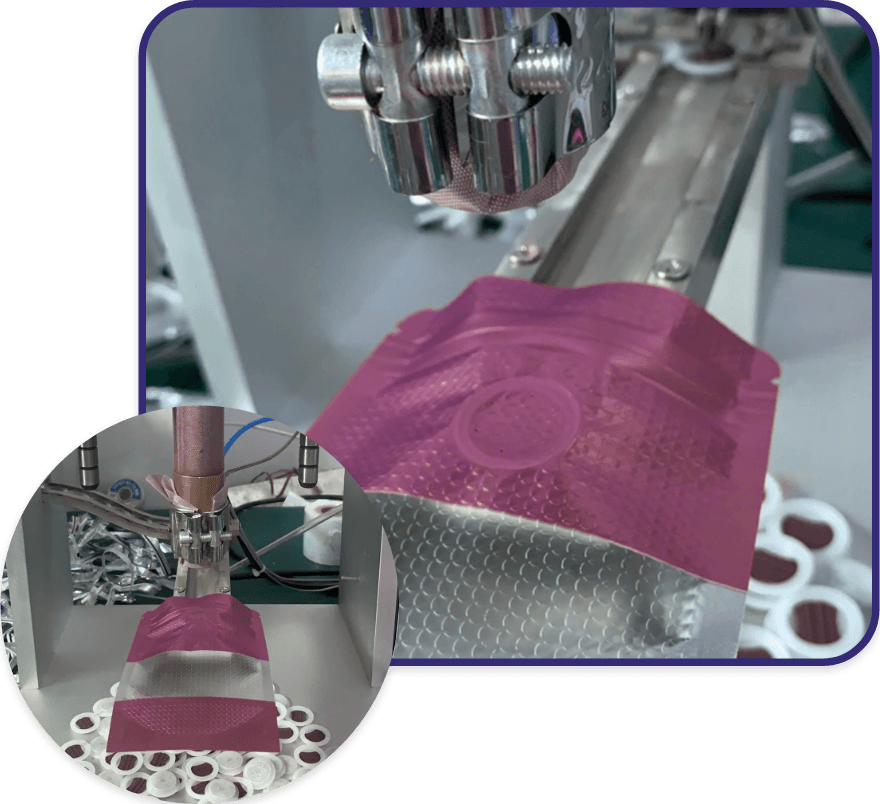

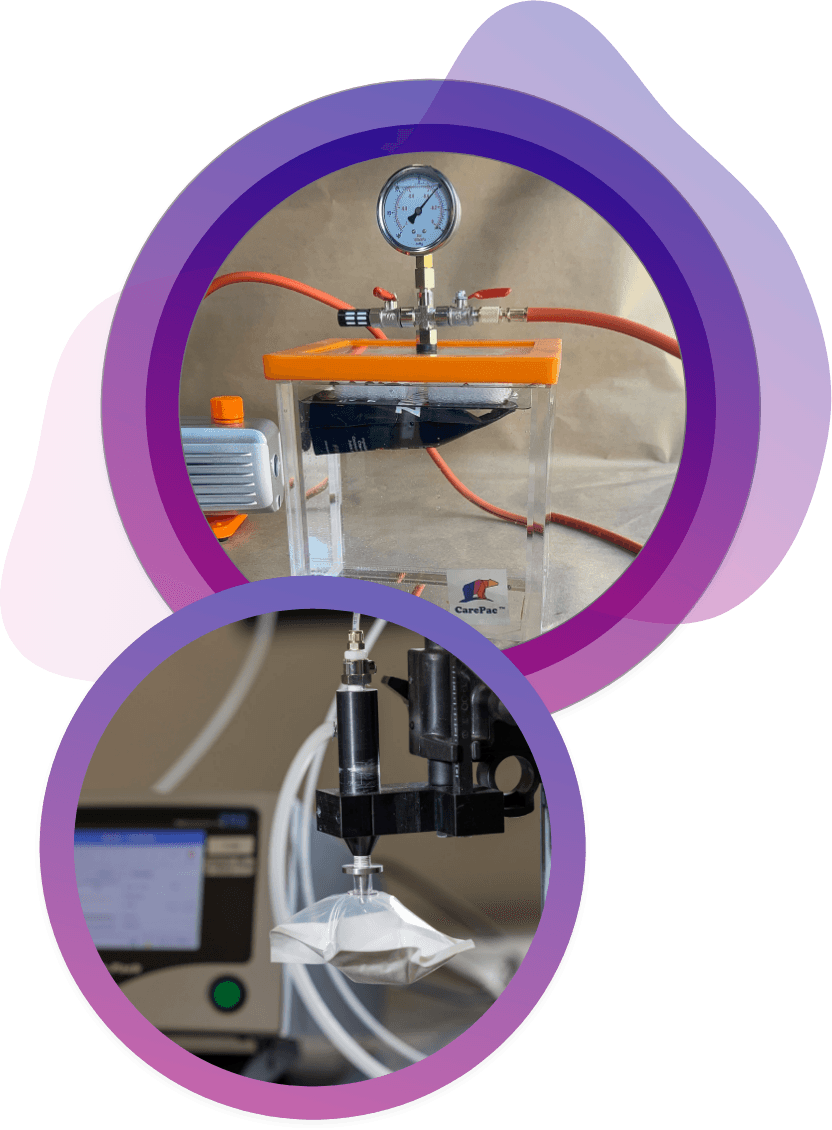

CarePac uses the Bedford Industries peel and stick applicator machine for our most rigorous tin-tie applications. This tin tying machine is incredibly precise and uses a high-quality adhesive that can easily apply the adhesive tape to most materials, regardless of its weight.

Each Bedford tin tying machine is capable of applying about 1,500 tin ties per hour. With these state-of-the-art tin tying machines, you won't need to deal with the headache of hot melt adhesive and you'll save time and labor on fast product application.

With our model machinery, your desired length bag enters the machine and the tin-tie is applied in one continuous motion. You won't need to spend time training a variety of staff on how to apply tin-ties or address common issues that pop up due to user error. Using an automated machine can improve your time-to-market, allowing you to get your items into the hands of your target market more quickly.

Performance Benefits for Coffee Roasters

There are several reasons why our tin tying machines can dramatically improve packaging workflows for small-to-medium coffee roasters just like you. Whether you're scaling up production or simply trying to streamline repetitive tasks, investing in impressive and automated packaging equipment is one of the fastest ways to boost efficiency without sacrificing quality.

Our tin tying solutions are built with the everyday challenges of independent roasters in mind—and they’re designed to make an immediate impact where it matters most. Here are just a few of the areas where your business will notice the difference after leveraging this unique innovation:

Labor savings and automation ROI

Automating your tin tie application can significantly reduce the time and manual labor costs associated with manual packaging. What used to take a team member several minutes per bag can now be done in seconds, allowing your staff to focus on higher-value tasks. Over time, this kind of efficiency adds up to a measurable return on investment.

Consistency of application

A key advantage of using automation machinery is the uniformity it brings to your final product. Our machines apply tin ties with the same precision every time and without hot melt adhesive, ensuring a clean, consistent seal that reflects the quality of your brand. No more crooked ties or uneven folds—just professional packaging that your customers will notice.

Minimal downtime or maintenance expectations

We understand that small roasters can’t afford things like frequent interruptions, which is why our machines are built for durability and long-term performance. With minimal maintenance requirements and quick-change parts, you can count on efficient and reliable uptime and fewer production headaches.

Operator ease of use

No need to be a mechanical expert to use the machinery. Our tin tying machines are user-friendly, intuitive, and easy to train on, so our team can get up and running with minimal ramp-up time—making it easier than ever to integrate automation into our existing workflow.

Freshness, Appearance, and Brand Value

Automating your tin tie application can help improve shelf presentation. If you take the time to compare hand-applied vs machine-applied tin-ties, you'll notice the difference right away. Not only do tin-ties adhered via machine application look better, but they often are more durable and create a stronger seal. This type of application can save you money in the long run, as your coffee will remain fresh and your customer service team won't be dealing with as many unhappy customers.

How CarePac Supports Coffee Producers Beyond Our Packaging Equipment

At CarePac, our packaging equipment is state-of-the-art, but the benefits of working with us extend beyond our equipment. If you're looking for a coffee packaging partner that understands your brand and will help you thrive, you've come to the right place. By partnering with a coffee packaging company that understands coffee, like us, here's what you can expect:

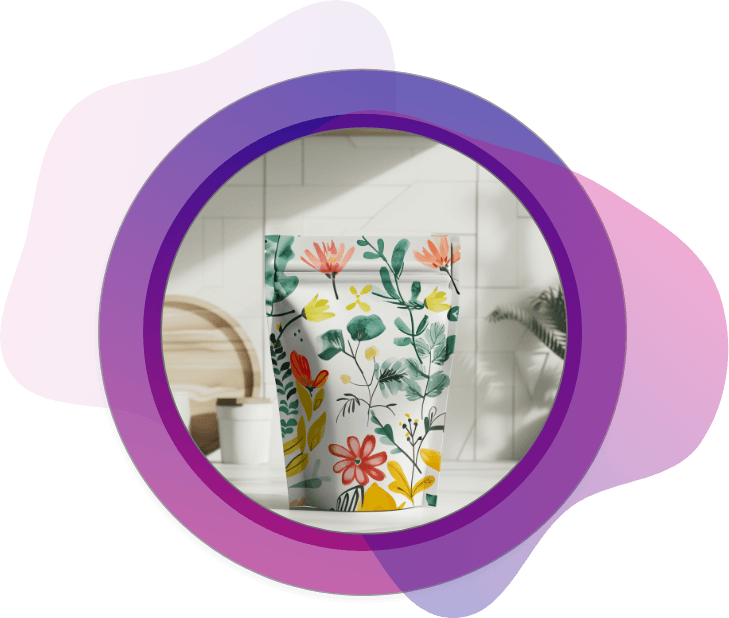

Customization capabilities - We're proud to offer customization options that span the entire bag. From the look and feel of the bag to what's written on it, we can customize every square inch and will keep you up-to-date with our progress every step of the way.

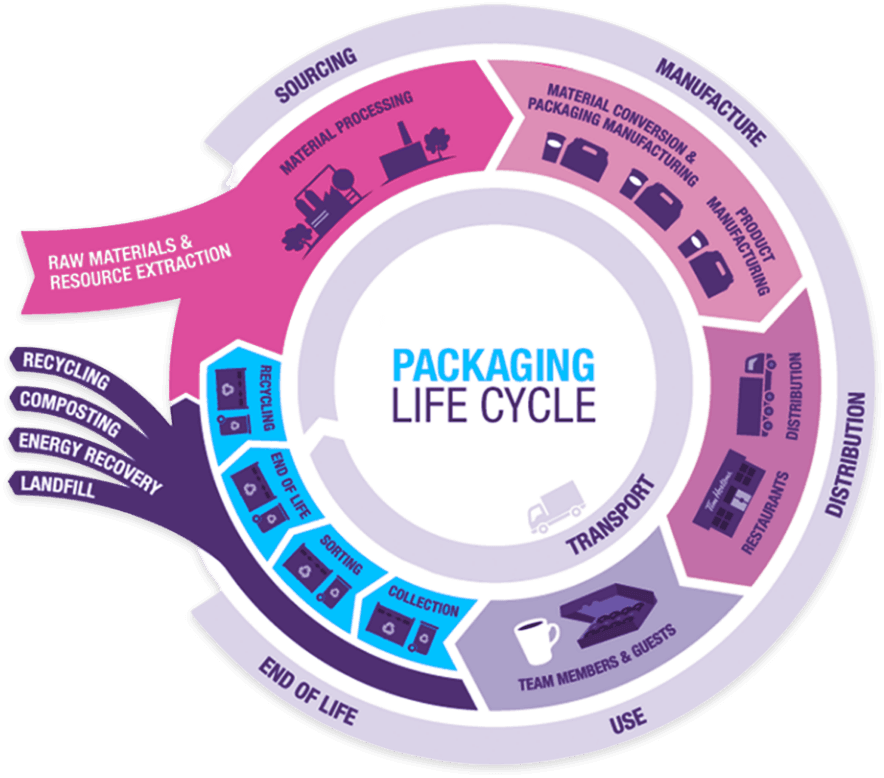

Sustainable material options - As climate change continues to have a negative impact on the world around us, we've created more sustainable materials and have incorporated more green practices into our entire manufacturing process.

Flexible lead times - If you need your order fast, we offer a flexible lead time menu so you have the ability to choose the items that make sense for you.

Low MOQs - We understand that you likely aren't ready to buy 100,000 coffee bags today, and we're proud to offer low minimum order quantities for our smaller customers. As you grow we can adjust our sizing and product volume to match.

Excellent customer service - Our customer service team will be with you every step of the way. Whether you need an issue resolved or simply need someone to walk you through the process, our support team is here to help.

Get a Sample or Packaging Consultation

Ready to partner with CarePac to elevate your coffee packaging? Have questions about our equipment or machines? Talk to a packaging expert today to discuss your specific needs, troubleshoot any issues you've experienced with past suppliers, and find the perfect tin-tie packaging solution for your coffee. Contact us today to get started.

Let's Get Started

Made In

The USA

Full Pouch

Customization