No products in the cart.

Packaging Design

The Specifications for Extended Shelf-Life in Food Packaging

The Specifications for Extended Shelf-Life in Food Packaging

What is Extended Shelf Life Food Packaging?

Food packaging materials have several key roles, one of which is extending shelf life of the food products that are packaged within. Extending shelf life depends on many different factors, including the type of food, the environment the food is stored in, and the material the food is packaged in.

In addition to attempting to extend shelf life, barrier packaging also helps to keep food free from contamination and microbial growth, makes it more convenient to transport, and helps perishable goods maintain its nutritional value while its in storage for an extended period of time.

Simply put, selecting the right plastic packaging will help food producers keep their food fresh, effectively fighting food waste. It helps protect food products from light, moisture, and oxygen, effectively improving the flavor while maintaining its texture. Your consumers deserve the very best, and that's where we come in.

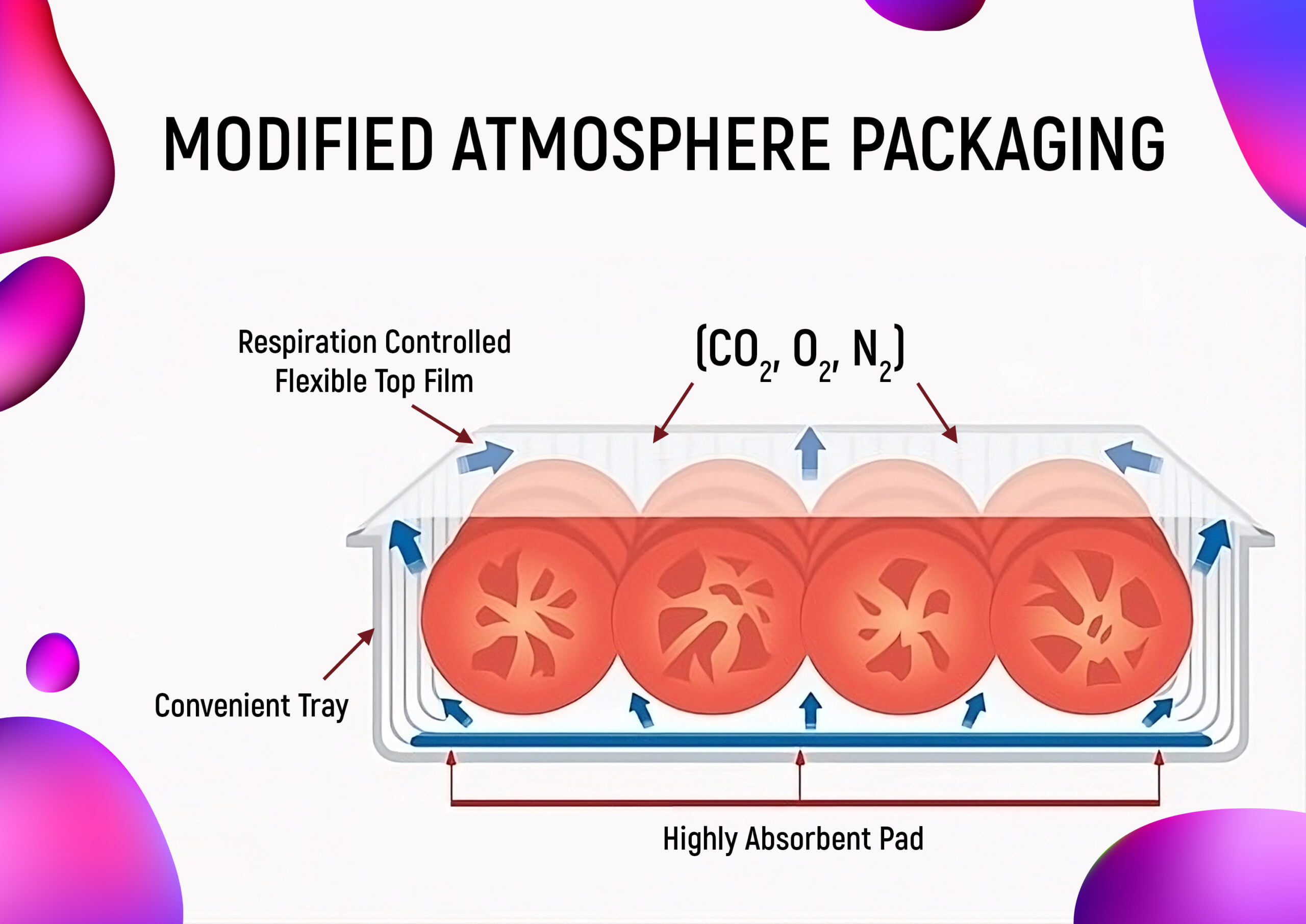

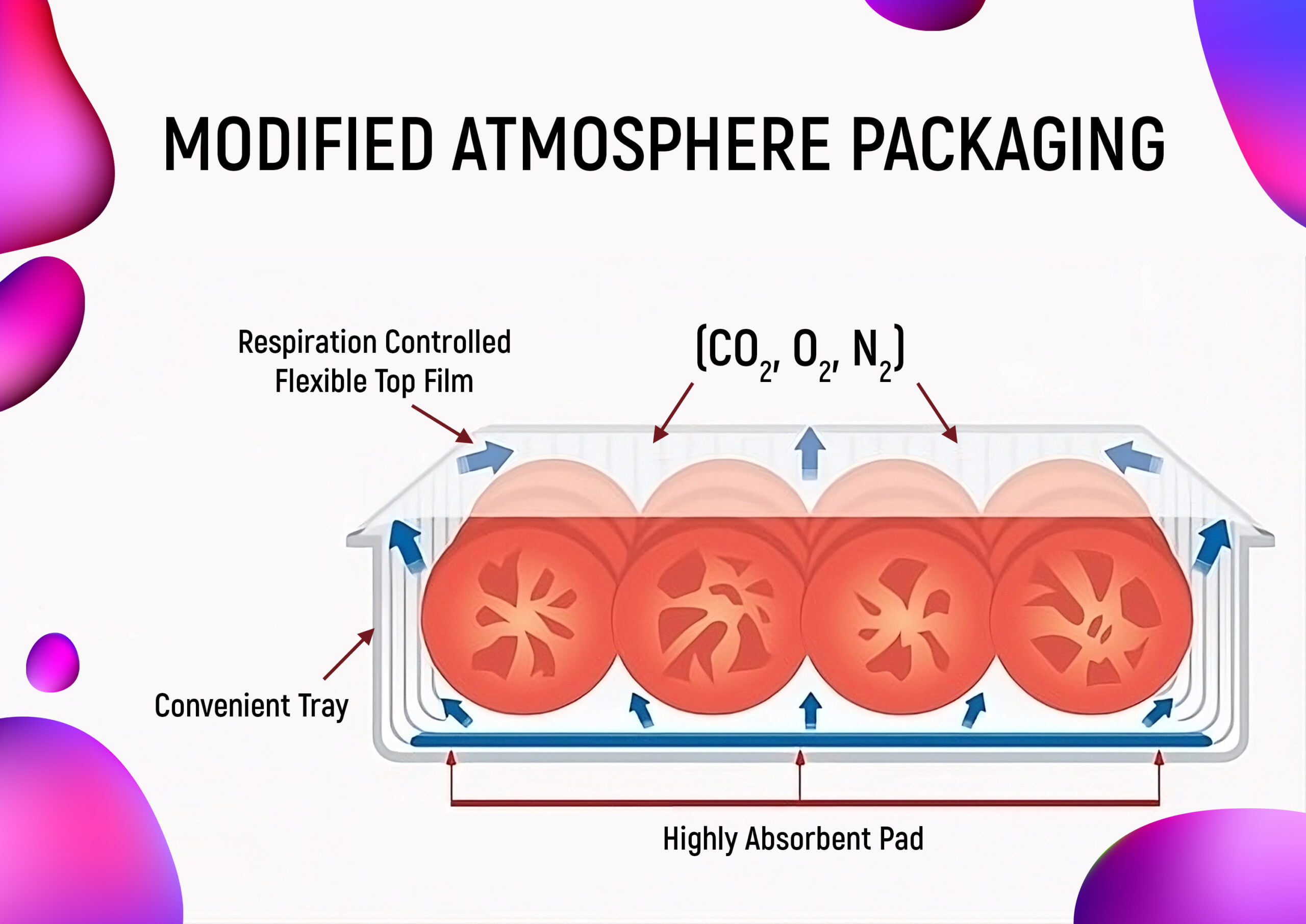

Things to Consider When Selecting Modified Atmosphere Packaging

There are several things you must consider when selecting modified atmosphere packaging for your packaged food. From material to sealing techniques, we'll break down the main considerations below. When combined, they all work together to extend shelf life of food products consumers love.

Material Choice to Help Extend Food Shelf Life

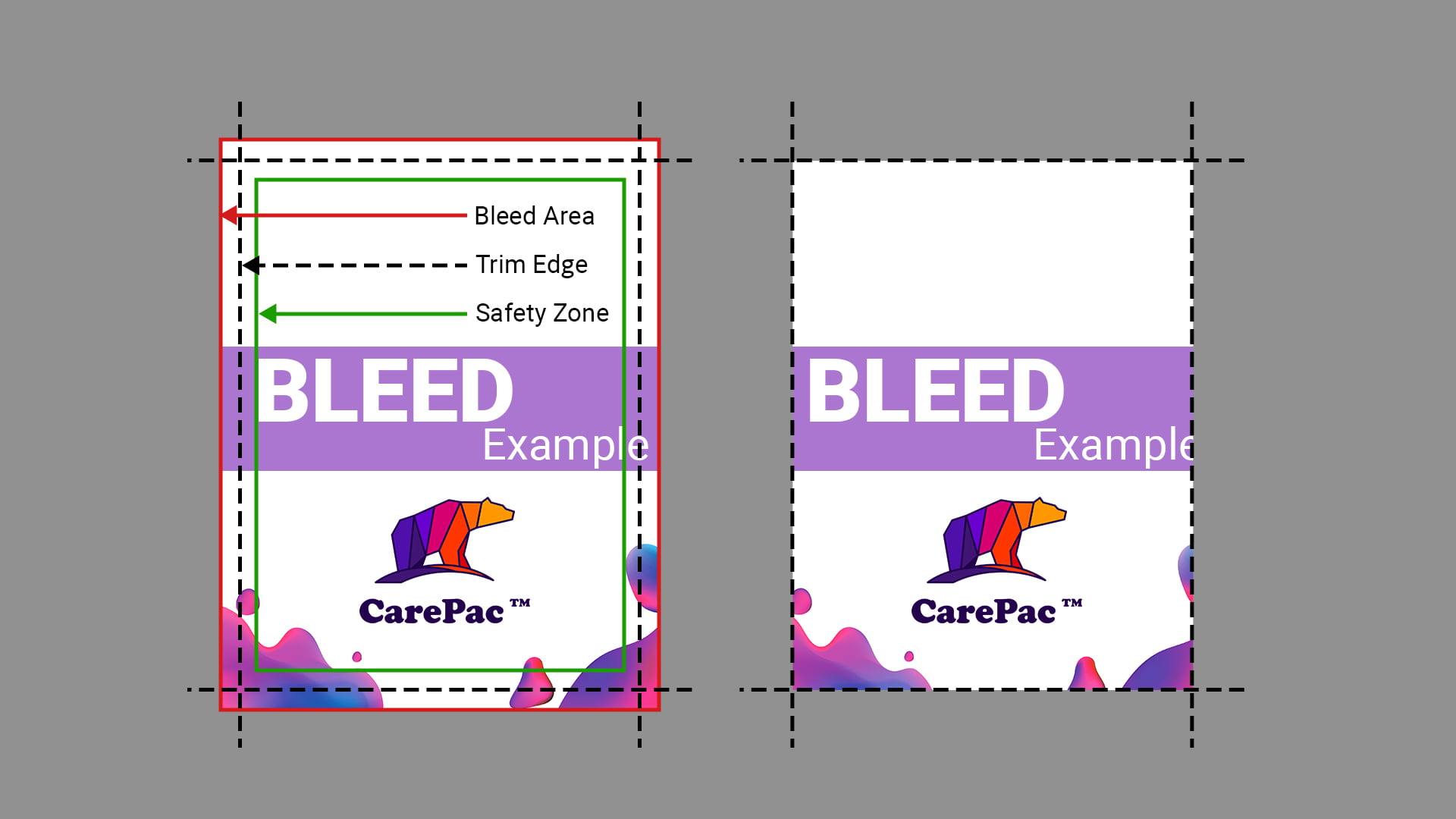

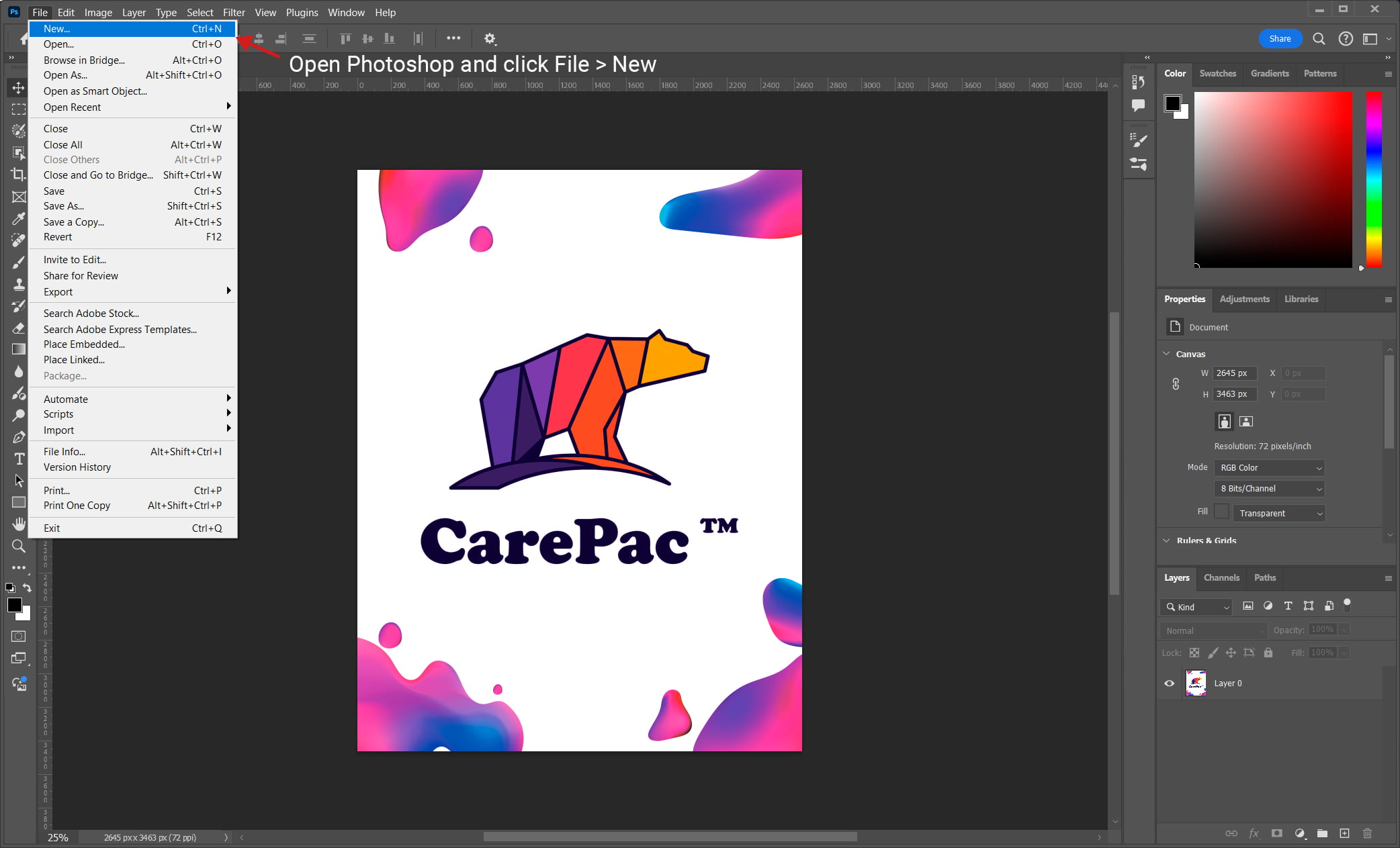

Material choice is incredibly important to helping food stay fresh longer. Whether you're packaging fruit, vegetables, dry foods, or some other kind of food items, the right packaging material can help the food products inside remain fresh and maintain their flavor.

If the material is too thin it won't have a strong oxygen barrier or proper gas permeability. You want to avoid tiny holes that impact physical protection, while going with the thinnest material possible to save money. We can help you select the proper food packaging for your consumers needs.

Barrier Properties to Help Avoid Food Waste

As previously mentioned, you'll want your food packaging to have the appropriate barrier properties. Generally speaking, high barrier plastic packaging helps retain flavors and aromas and extend the shelf life of food by creating a tight seal. The barrier protects food from oxygen transmission, organic acids, and helps extend food shelf life during long term storage.

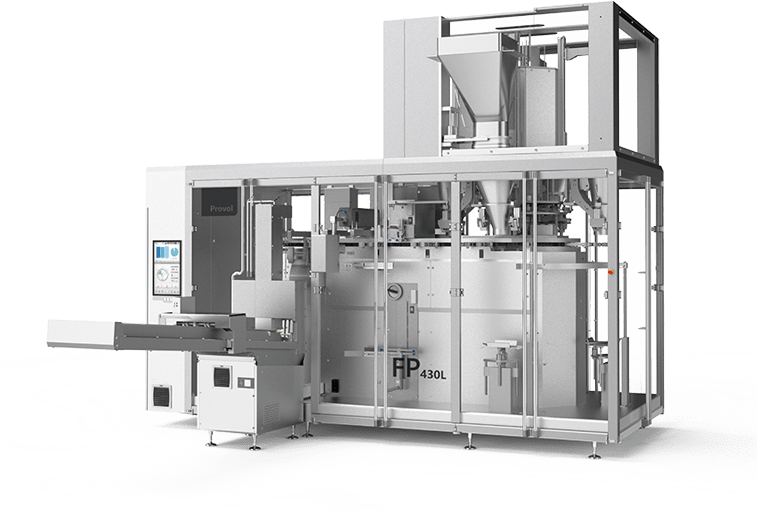

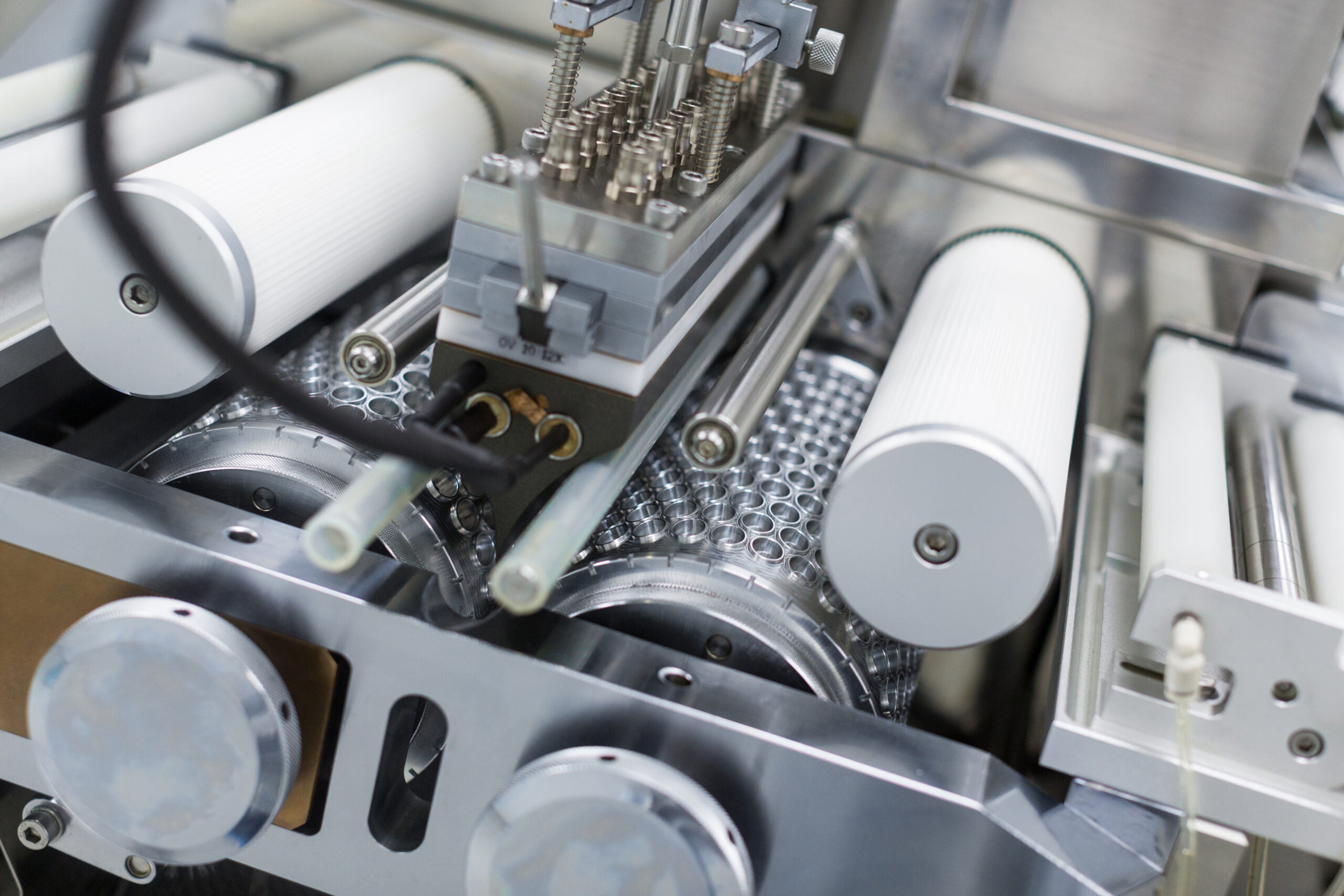

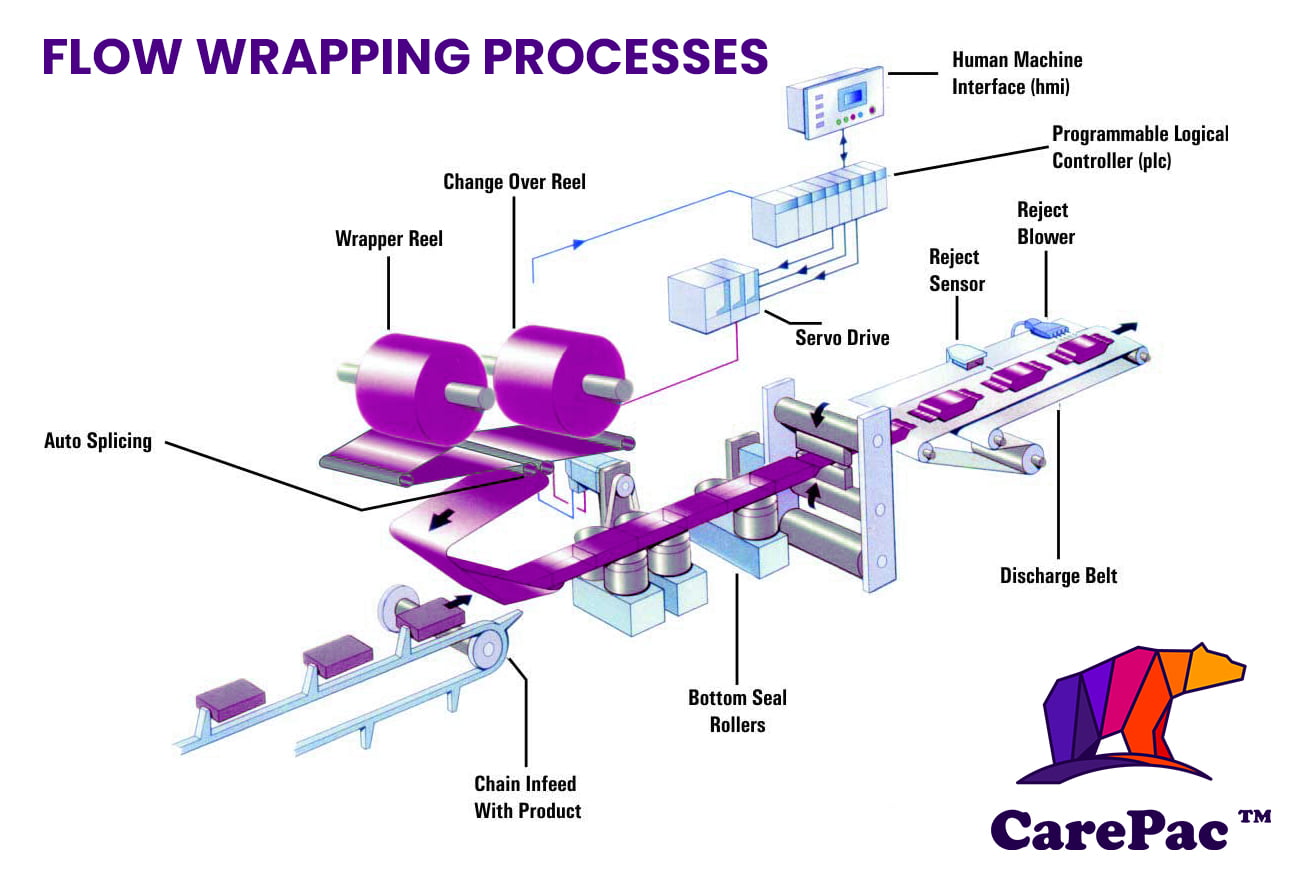

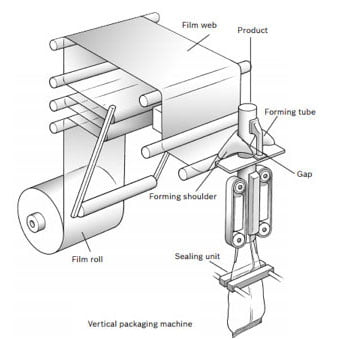

Packaging Technology

In addition to selecting the right packaging material and ensuring your bag has barrier properties, you can also include specific packaging technology in your bag. An example of this technology includes opting for modified atmosphere packaging, vacuum packaging, or active and intelligent packaging technologies like oxygen absorbers.

If you're unsure about what kind of food preservation technologies are currently available for the food industry, we can walk you through all the sustainable packaging solutions we have available. When keeping food fresh is key, we can help!

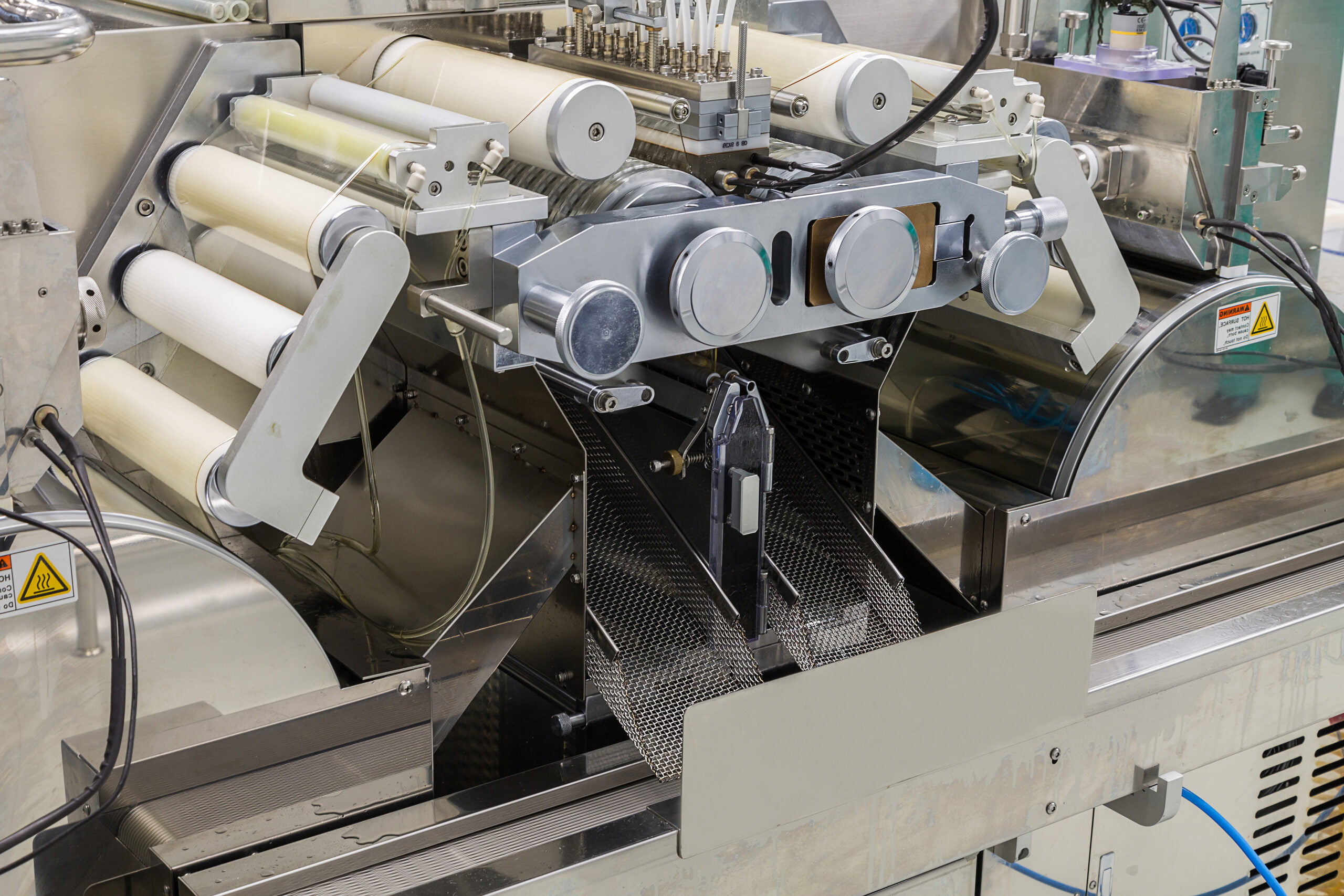

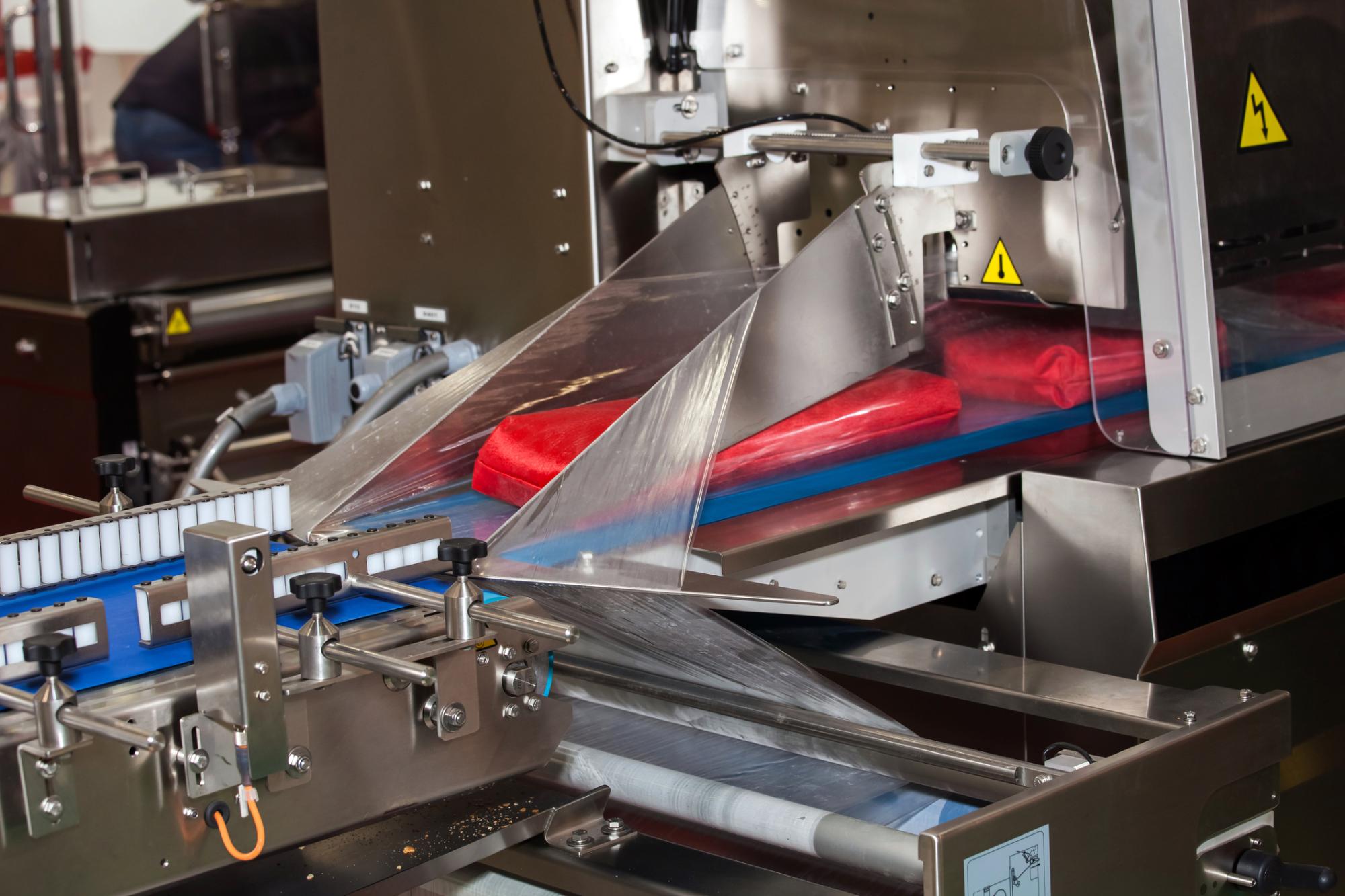

Sealing Techniques

We cannot stress the importance of proper sealing. You can select the very best packaging materials and opt for an oxygen absorber and materials with antimicrobial properties, but if there is not a proper seal it's all for nothing. The seal has a direct impact on product shelf life, protecting food from food spoilage. Some popular sealing techniques include heat seal, cold seal, and ultrasonic seal.

Storage & Handling

Once you have your packaging materials in hand, it's important to practice proper storage and handling techniques. This applies to storing and handling the food packaging before it's in use and after it's been filled with your food product. You'll want to keep your bags in a sterile environment, away from mold and bacteria growth, moisture, and UV light. Once packed, the food item should be kept at the proper temperature, and transported with care. Ultimately, you can give your food items a longer shelf life by paying attention to food safety requirements.

Regulatory Standards

Finally, each industry has a variety of regulatory standards that companies must meet. For the food industry, specifically, they'll take into fruit, vegetable, and meat science into consideration when coming up with specific standards to protect food. These standards will protect the nutrient content and freshness of the food items while in long term storage, which will effectively cut back on food waste and food spoilage.

CarePac: Your Partner in Food Product Packaging

At CarePac, we're proud to be your partner in food packaging. With decades of experience with packaging food products, we know just what to do to protect food quality and extend food shelf life. We'll help you select the perfect material because we understanding the role packaging plays in protecting against food spoilage and waste.

From protecting your fruits and vegetables from microbial growth and UV light, to designing plastic packaging that will entice your customers to purchase YOUR product, we're your partner in all things packaging. Contact us today to get started!