No products in the cart.

Exhibitions and Tradeshows

Specialty Coffee Expo Trusted Pouch Provider- CarePac

Specialty Coffee Expo

Trusted Pouch Provider - CarePac

Speciality Coffee Expo (SCE) is the largest tradeshow that’s focused exclusively on America’s favorite beverage -- coffee! As a coffee packaging provider, our favorite part of the event is the coffee design awards for branding and packaging, but we might be a little biased. 😉

If you have your eyes on that prize, connect with us at the event to discuss your coffee packaging needs. Unlike other coffee packaging providers, we allow for full customization, from the bag size and material to branding. We work with coffee companies of all sizes to help them craft an aesthetically pleasing bag that’ll keep their beans as fresh as the day they were roasted.

Why CarePac?

Because we’re awesome. In all seriousness, though, we pride ourselves on being a small, family-owned and operated business that takes packaging as seriously as you take coffee. We live and breathe packaging, and all our products are proudly made in the USA. We strive to make every customer a repeat customer, and you’ll notice this as our helpful CareDesign team guides you through the process.

And when we say we work with companies of all sizes, we mean it. In fact, we offer prototyping as few as 100 units! This allows coffee brands, like yours, to test new blends or offer seasonal flavors without having to invest your entire packaging budget into a single style of bag.

Types of Coffee Pouches We Offer

Although we offer hundreds of different bag variations, we do offer specialty pouches that are catered specifically to coffee brands. Here are a few of the packaging options we recommend for our roster of clients in the coffee industry:

These bags have a square bottom, stand up on their own, and can be fully customized to represent your brand.

Although this is an older pouch configuration, it’s extremely popular in the coffee industry for its versatility.

These are four-corner bags that have two premade side gussets that provide reinforcement so your product stands tall on shelves.

Other Customization Options

Let’s face it - the coffee industry is saturated with competition, and standing out often comes down to packaging. We offer a variety of customization options that can help take your packaging to the next level, including a variety of bag materials and finish options. Here are a few options to consider:

For the eco-conscious consumer who prefers to buy coffee in bulk, the zipper helps keep things fresh while the environmentally friendly material allows them to compost their bag when they’re done with it.

Whether your target market is the commercial food industry or doomsday preppers, our line of vacuum seal bags will keep your coffee fresh for as long as possible. Bonus: opt for lay flat pouches for easy storage.

High-quality finishes like soft touch or metallic effects can encourage customers to pick up your product while browsing the crowded aisles at the grocery store.

Catch Us @ Specialty Coffee Expo

Want to hold and inspect our high-quality bags in person? Have questions about our customization process? Just want to say “hi”? You can catch us at the 2024 Specialty Coffee Expo!

Coffee Pouch & Packaging FAQs

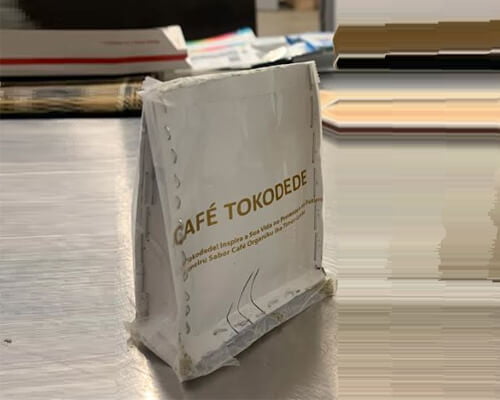

Can you provide examples of custom pouch designs you’ve created for other brands?

Yes, we will have examples available at the SCE, and here are a few visual examples as well.

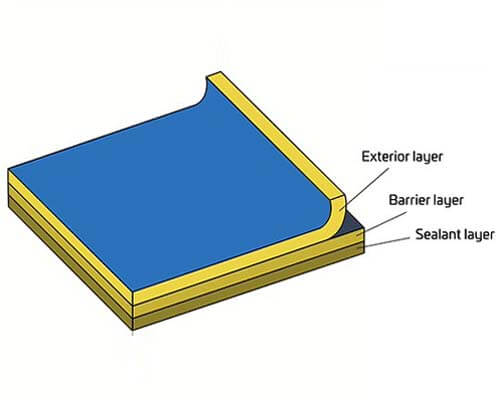

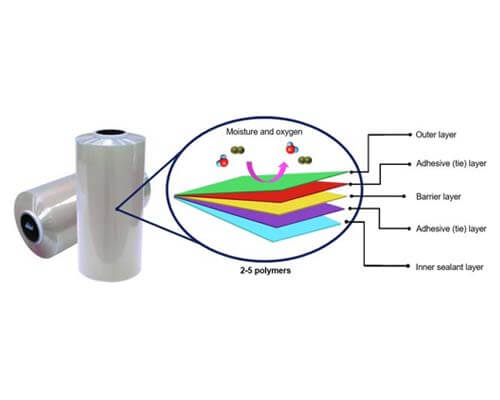

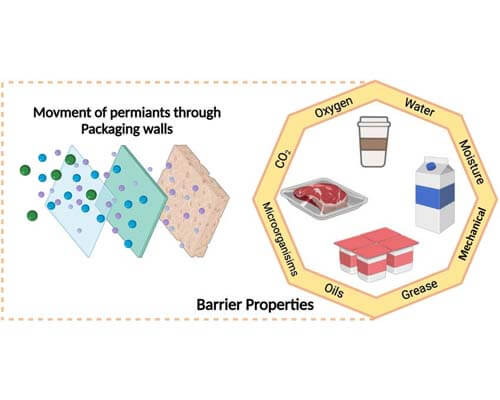

What materials do you recommend for preserving coffee freshness, and can you customize them for our specific needs?

Our CareSilver and CareFoil materials are our highest barrier materials, meaning they’ll really keep your coffee fresh.

What is the typical lead time for designing and manufacturing custom coffee pouches?

CarePac offers a unique lead-time menu. Unlike some of our competitors (Roastar and ePac, to name two!), we offer total customization, from the size and material to the features included in your bag. As such, we have to plan our production more carefully than the companies that fit everyone into a few set sizes and use only one print method. Our fastest production lead time is 3 weeks.

Do you offer environmentally friendly packaging options, and are they suitable for coffee products?

Yes, we currently offer compostable and recyclable materials. While these are great options, they do have less of a barrier. As such, we recommend using these materials for small or seasonal batches.

Can you accommodate various sizes and shapes to match our coffee product range?

Yep! When we say “total customization”, we mean it. Unlike other companies that force you to fit your product into their bags, we create bags specifically for your product.

What printing and finishing options are available for customizing the appearance of our pouches?

Because we offer both plate and digital printing, we offer SO MANY finishing options, including glossy and matte. To learn more about our finishing options, check out our full range of options.

Do you have quality control measures in place to ensure consistent and durable pouches?

Yes. CarePac is ISO 9001:2015 certified, and we pride ourselves on adhering to these top management standards.

Are there minimum order quantities or volume discounts for custom pouch orders?

CarePac offers prototyping from 100 bags, meaning you aren’t tied to printing bags in extremely high numbers. (

Will CarePac be attending Specialty Coffee Expo? If so, what booth?

...

Are your bags manufactured in the US?

Yes, we’re extremely proud to be making pouches in the USA!