No products in the cart.

When designing a packaging dieline, there are a lot of factors to consider. Issues with sizing, spacing, color fidelity, and regulatory compliance all play a part in your dieline packaging design process. We often see the same set of packaging design mistakes and want you to avoid those in your next project. Those custom dieline mistakes can be divided into issues with your art setup and issues with your proofing.

Art Setup Mistakes (Top 5)

Getting your images and your packaging art just right is both an art and a science. Here are the top five issues we see with art setup during custom dieline creation.

1. Use Adobe Illustrator

When professionally printing packaging elements you need everything you design to be in Adobe Illustrator (AI). Adobe Illustrator is the industry gold standard for artwork. Other paid and free solutions such as photoshop, Inkscape, BoxySVG, and other document file formats such as PSD, EPS and SVG are perfectly suitable, but in order to adhere to industry best practices and standards for artwork design, AI is the preferable program. One of the main reasons for using AI is that original art developed in AI is natively vectorized.

2. Create All Art as a Vector

Vector art or "vectorized art" is art that is created based on mathematical formulas for the exact size of the cut lines (don't worry no math is required to make vectorized art!) Vectors never loses resolution no matter what level you zoom in because a vector is not a picture. There is no pixilation with a vector. Logos must be a vector. So do any words printed on the packaging, especially nutrition information.

Digital photography does not produce a vector. It takes in light through the camera's lens and converts it into a digital file. That file, however, becomes pixelated when you zoom in. This is incredibly important to consider for your finished packaging.

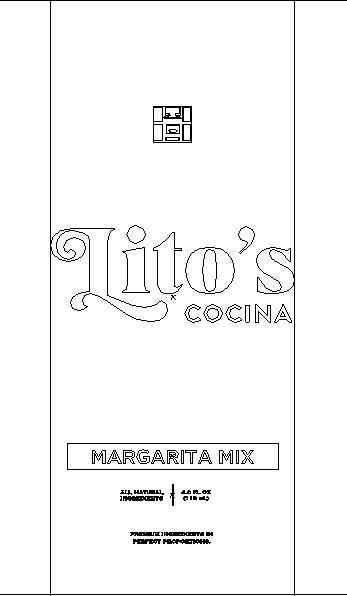

Here is an example of a vectorized design when viewed in the designs "outlines" mode.

Vectorized Art Work as a finished

product with color

Outlines preview showing that the art is made of lines and curves

A good rule of thumb? Make sure that everything that is not an image on your packaging designs is a vector.

This makes it easy to create a PDF ahead of production.

In order to maintain compliance with governmental regulations, the nutrition information you enter or send cannot pixelate should you adjust the dieline's size. Barcodes, which must be scannable on your finished product, are especially susceptible to pixilation. Make sure that you design your dieline's barcode as a vector rather than a picture.

QR Code that is not vectorized

A vectorized QR code

Zoomed in on QR code shows pixilation

Even when zoomed no pixilation occurs

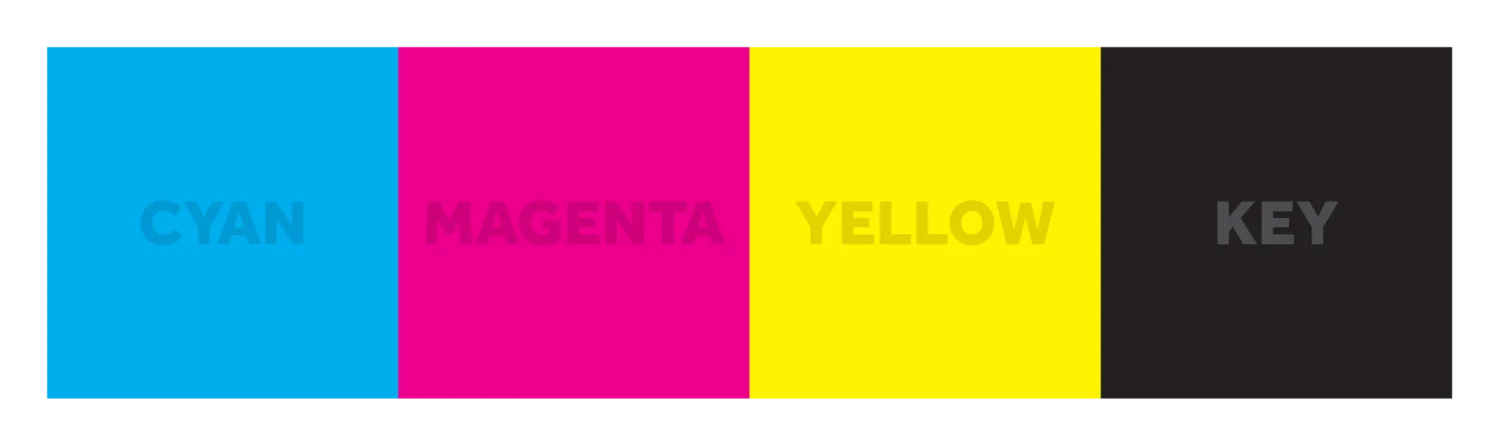

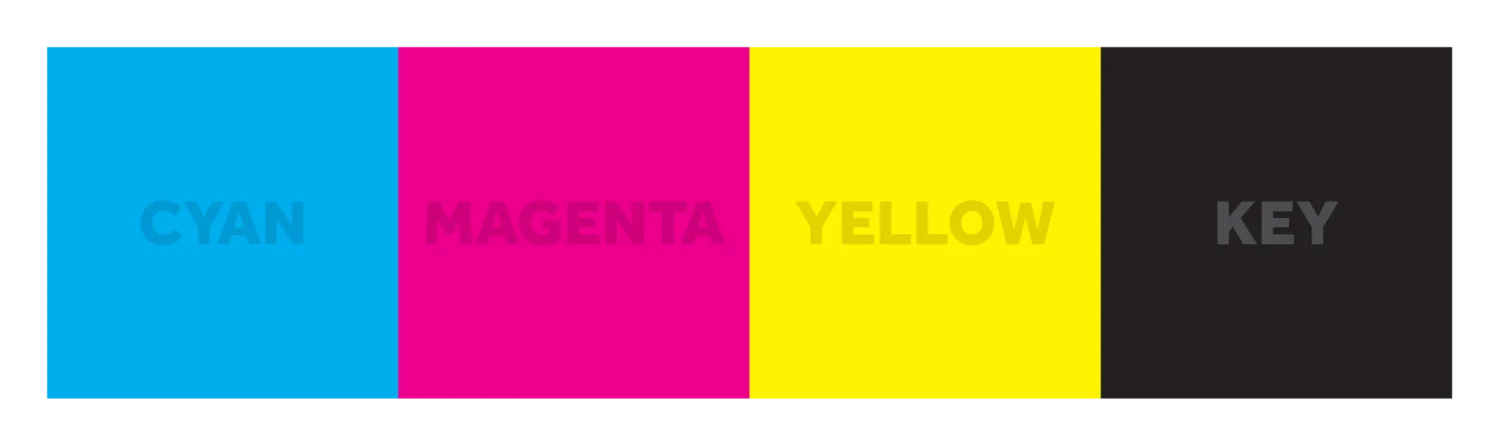

3. CMYK versus Pantone

CMYK stands for "Cyan, Magenta, Yellow, Black," and it represents the four basic colors used when printing graphics, images, and other media. Pantone, on the other hand, is a color matching system. Pantone includes a comprehensive set of ink pigments called "color bars" which resemble paint samples from the hardware store.

CMYK takes those four color choices and blends them together in a subtractive process in order to make all the colors of the rainbow. The drawback is that every printer has slightly different output. The resulting color is a function of the blending process rather than an industry-wide standard.

Your finished document will most likely be on some blend of plastic packaging, not on printed paper. Things don't always translate correctly, especially if you are using CMYK. This is where Pantone truly shines. Each color bar in the Pantone collection includes the exact formulation for that pigment. Any element on your dieline that is not a digital photo should be rendered in Pantone coloring rather than CMYK for the sake of continuity.

4. If You Have To Include A Picture, Make Sure The Resolution Is Correct

Not everything can be a vector. Sometimes your packaging calls for the use of a digital picture. Make sure you use the correct print resolution to prevent your included photos from pixilation. 300 DPI is the minimum choice for high resolution prints. 300 DPI resolution includes 90,000 dots per square inch which can help stave off pixilation should your finished packaging require you to zoom in. Preferably you want the highest DPI / PPI possible, 600, 800 or more.

5. Do Your Diligence When Including Images

Normally when you use images rather than vectors to create your own dielines, they are embedded directly into the dieline products. You can also choose to link those images to a specific file or folder. When the packaging dieline renders in AI for production, it draws the image from another source. One problem we see routinely is that people forget to properly link the image. If you choose not to embed an image on your package, make sure you've done your diligence.

Proofing Mistakes (Top 5)

Creating graphical elements is only the first step in the design process. Every dieline requires thorough proofing before it is finalized. Here are the five most common mistakes we see with the proofing phase.

1. Proofread

One of the most commonly overlooked processes is proofreading the text on your bag. Small errors in spelling can result in huge errors in customer understanding, but beyond that, a seemingly innocuous mistake could throw your packaging out of compliance with governmental regulations.

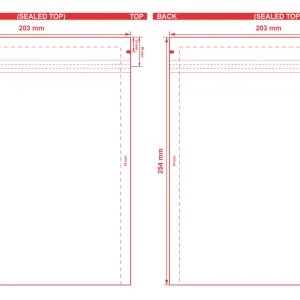

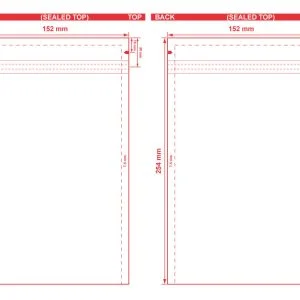

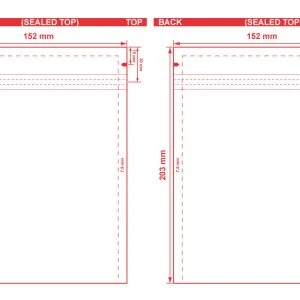

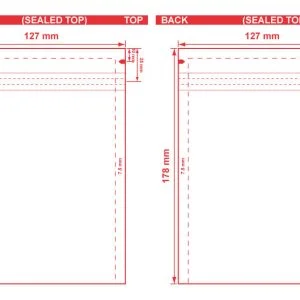

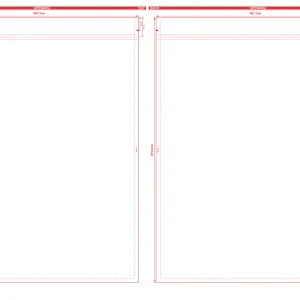

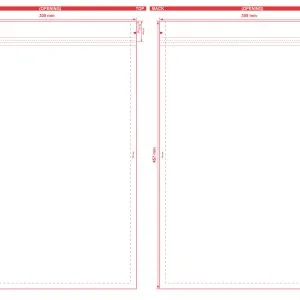

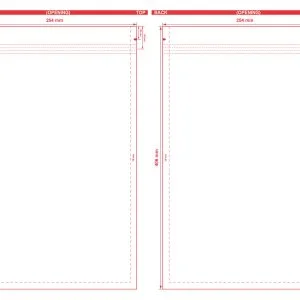

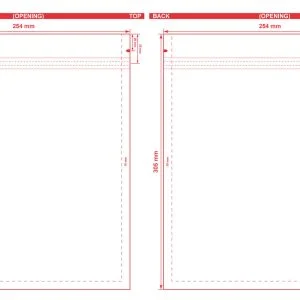

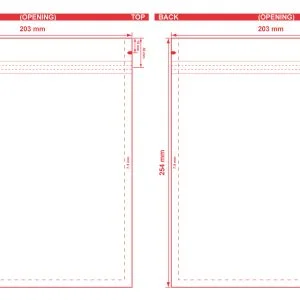

2. Check Your Sizing and Spacing

It begins with ensuring that the size of your products packaging is adequate and unaltered after adjustments in your design software. Too many industry professionals forget to make sure that the overall bag dimensions fit the product they're intended for. One sure fire test you can use is to measure your dieline against a competitor's product to ensure it fits.

3. Outline Your text

Fonts can be tricky things. They are dependent on files in order to display correctly. Different devices render the same font differently depending on the file packs that are installed. Outlining is a way to ensure continuity between displays. By outlining your fonts, which is a relatively simple process via AI's editing software, you convert the font into art, much the same as a vector. That way image fidelity is maintained no matter what workspace you are using. See our how-to on outlining text.

4. Ensure Compliance

We've mentioned it before, but compliance is an important part of the dieline process. Far too many people fail to check that the barcode they've included serves its intended function. Rather than interacting with the merchant's POS system, a barcode that hasn't been properly vetted may spit back gibberish.

In the same vein, there is a virtual cavalcade of regulations from entities like the FDA and the USDA which impact the icons and images on your finished packaging. When proofing, make sure to take the necessary time to ensure that your packing meets all regulatory compliance.

5. Don't Cram Too Much Into Your Dieline

Along the same lines as sizing and spacing, make sure you don't place visual elements like logos, verbiage, and graphics jammed into the edges of your bag. Not only does it make the packing incredibly difficult to read, it may also violate the above-stated compliance issue.

Designing a High-Quality Dieline

Graphical design is as much an art form as it is an exact science. There are dozens of exact specifications that need to be met in terms of color, spacing, typeset, and overall resolution. With so many variables to keep track of, it is all too easy to make a mistake.

The dieline design tips and specific dieline requirements listed above are in on way comprehensive, but they are a good starting point to make sure that your finished dieline truly shines.

Check Out Our Wide Selection of Dielines Below

-

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23ccc%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(.54633%20-24.07467%20202.6378%204.5985%20150%2017.2)%22%2F%3E%3Cellipse%20fill%3D%22%23cbcbcb%22%20cx%3D%2250%22%20cy%3D%22167%22%20rx%3D%2259%22%20ry%3D%2218%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(97.1%205.5%20172.9)%20scale(158.42394%2083.44662)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%2268%22%20cy%3D%2295%22%20rx%3D%22255%22%20ry%3D%2255%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

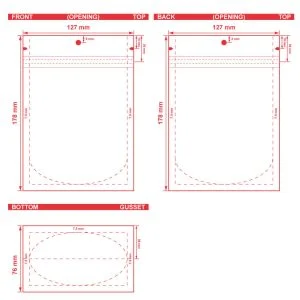

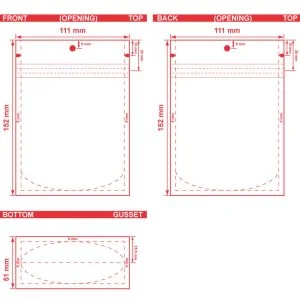

Custom Stand-Up Pouch 5x7x3 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23cbcbcb%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-282.15754%20.16511%20-.0184%20-31.45542%20153.5%2018.9)%22%2F%3E%3Cellipse%20fill%3D%22%23ccc%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-108.90927%207.19932%20-2.2729%20-34.38395%2016.6%20210.2)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-16.1%20754.3%20-737.1)%20scale(122.79217%20133.29181)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(247.24458%2017.72271%20-4.52471%2063.12299%20138.8%20119.7)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

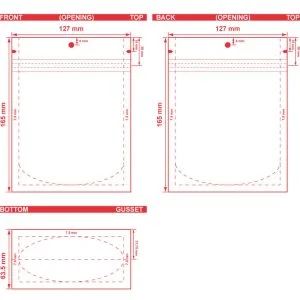

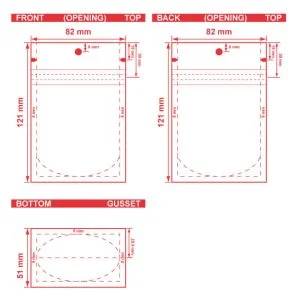

Custom Stand-Up Pouch 5×6.5×2.5 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23cbcbcb%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-1.17565%2035.4394%20-254.85982%20-8.45457%2076%206.4)%22%2F%3E%3Cellipse%20fill%3D%22%23ccc%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.29408%20-29.8619%2077.1188%20-5.92449%2039.3%20194.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-68.8%20204.1%20-70.6)%20scale(77.27672%20208.28111)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22225%22%20cy%3D%22166%22%20rx%3D%22115%22%20ry%3D%22115%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Custom Stand-Up Pouch 4.375x6x2 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23cdcdcd%22%20cx%3D%22123%22%20cy%3D%2214%22%20rx%3D%22135%22%20ry%3D%2241%22%2F%3E%3Cellipse%20fill%3D%22%23ccc%22%20cx%3D%2257%22%20cy%3D%22165%22%20rx%3D%2256%22%20ry%3D%2230%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M9%20271l262-17-22-235z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-179.7%2067%2048.5)%20scale(242.9916%2043.22945)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Custom Stand-Up Pouch 3.25×4.75×2 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23ccc%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-33.91917%20.8882%20-.41116%20-15.70143%20145%20.5)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M305.9%20318.2l-324-21.8L76.6-18.2%20300%20116.6z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M318.2-3l-52.8%20311.8L160%208.8z%22%2F%3E%3Cpath%20fill%3D%22%23dbdbdb%22%20fill-opacity%3D%22.5%22%20d%3D%22M128.3.6h30.5V17h-30.5z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

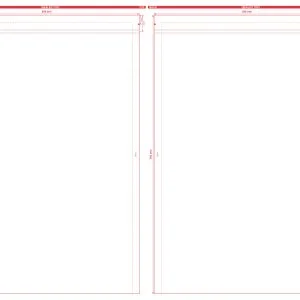

Metallized 3 Seal Open End Flat Barrier Pouches 20×30 S-18139 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cpath%20fill%3D%22%23c5c5c5%22%20fill-opacity%3D%22.5%22%20d%3D%22M300%2017H1.2v-32.8H300z%22%2F%3E%3Cpath%20fill%3D%22%23c4c4c4%22%20fill-opacity%3D%22.5%22%20d%3D%22M113%2017h65.7v7h-65.6z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(286.82297%20.41317%20-.20474%20142.13098%20160%20167.5)%22%2F%3E%3Cpath%20fill%3D%22%23dedede%22%20fill-opacity%3D%22.5%22%20d%3D%22M164.2-6.4l24.3%203.8-4.6%2029-24.3-3.9z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

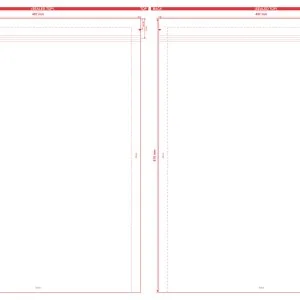

Metallized 3 Seal Open End Flat Barrier Pouches 18×24 S-18138 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.09247%20-26.48959%20172.69305%20-.60281%20129.8%200)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22122%22%20cy%3D%22186%22%20rx%3D%22160%22%20ry%3D%22160%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M1.9%2019.6L-16%20271l287-24.9L73.8%2021.6z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M178%2020h78v236h-78z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 12×18 S-6180 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c7c7c7%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(.1711%20-22.0553%20271.12463%202.10334%20139%2012.2)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M-2.2%20298.2L7%2034.7l298.7%2010.4-9.2%20263.5z%22%2F%3E%3Cpath%20fill%3D%22%23ccc%22%20fill-opacity%3D%22.5%22%20d%3D%22M120.2%2031.2l53.9%201-.2%208.1-53.9-1z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M.6%2040.4h300v260.2H.6z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 10×14 S-22300 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(.13482%20-25.74762%20221.91122%201.16194%20146.6%2018)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(285.60479%20-60.70717%2029.66189%20139.5482%20156.5%20192.2)%22%2F%3E%3Cpath%20fill%3D%22%23c9c9c9%22%20fill-opacity%3D%22.5%22%20d%3D%22M103.7%2042.8h87.9v5.8h-87.9z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M318.2%2053.3L82.6%20318.2-18.2%2043.9z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 10×12 S-16892 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-292.11237%203.0591%20-.28093%20-26.82553%20184%2015)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M297.7%20335.7H-1.2V40.4h298.9z%22%2F%3E%3Cpath%20fill%3D%22%23c7c7c7%22%20fill-opacity%3D%22.5%22%20d%3D%22M121.3%2040.4H161v8.2h-39.8z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-2.14081%20-136.27722%20277.65762%20-4.3618%20151.3%20185)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 8×12 S-22299 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(219.34481%204.9614%20-1.09227%2048.28979%20133%20.6)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M300%20312.9H1.2V56.3H300z%22%2F%3E%3Cpath%20fill%3D%22%23d6d6d6%22%20fill-opacity%3D%22.5%22%20d%3D%22M117.8%2041.6h51.5v15.2h-51.5z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M300.1%2042.5l-71.8-2.9-246.5%20242.5%20318%2036z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 8×10 S-6177 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(223.63776%20-.50692%20.07617%2033.60544%20130.8%204.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(32.48834%20107.19749%20-171.5826%2052.00154%20155%20153.9)%22%2F%3E%3Cellipse%20fill%3D%22%23dcdcdc%22%20cx%3D%22128%22%20cy%3D%2230%22%20rx%3D%2244%22%20ry%3D%2218%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(78.32848%20-30.1911%2019.83453%2051.45915%2040.5%2093)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 6×10 S-6176 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23ccc7c9%22%20cx%3D%2294%22%20cy%3D%2216%22%20rx%3D%22253%22%20ry%3D%2232%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-165.1%2078%2078.4)%20scale(214.8805%20123.61459)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-91.38822%2084.33063%20-75.83706%20-82.18384%20159%20161.8)%22%2F%3E%3Cpath%20fill%3D%22%23ffb9df%22%20d%3D%22M157%200h41v14h-41z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 6×8 S-6175 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23ccc6c9%22%20cx%3D%22130%22%20cy%3D%2220%22%20rx%3D%22253%22%20ry%3D%2229%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-23.22611%20-115.77248%20215.70351%20-43.27413%20128.9%20170.6)%22%2F%3E%3Cpath%20fill%3D%22%23d2d4d3%22%20d%3D%22M82%2045.6l68-1.2v10l-68%201.2z%22%2F%3E%3Cellipse%20fill%3D%22%23ffb8df%22%20cx%3D%22180%22%20rx%3D%2225%22%20ry%3D%2214%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 5×7 S-16891 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23d4c2c9%22%20cx%3D%22101%22%20cy%3D%2220%22%20rx%3D%22238%22%20ry%3D%2235%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22119%22%20cy%3D%22164%22%20rx%3D%22255%22%20ry%3D%22111%22%2F%3E%3Cellipse%20fill%3D%22%23ffc2df%22%20cx%3D%2280%22%20rx%3D%22162%22%20ry%3D%2214%22%2F%3E%3Cpath%20fill%3D%22%23d9e4df%22%20d%3D%22M115%2059L18%2040l138-53z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 4×6 S-11661 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23cecdce%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-294.91633%202.9293%20-.4292%20-43.2111%20149.9%2057.4)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(5.12388%20115.3354%20-298.53367%2013.26262%20136.6%20212.3)%22%2F%3E%3Cellipse%20fill%3D%22%23d6d6d6%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(22.53351%20-8.74195%207.51881%2019.38072%20101%2099)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(297.62518%20-20.81198%206.98652%2099.91187%20161.4%20213.8)%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 3 1/2×4 S-18137 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23ccc%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(2.01397%2050.14345%20-206.3917%208.28955%20147.5%2030.8)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-253.28018%2029.56607%20-11.6955%20-100.19045%20132.7%20179.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22103%22%20cy%3D%22173%22%20rx%3D%22255%22%20ry%3D%2292%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M0%2075h62v181H0z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 3×5 S-11660 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23d5cdd1%22%20cx%3D%22124%22%20cy%3D%2244%22%20rx%3D%22255%22%20ry%3D%2238%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22125%22%20cy%3D%22171%22%20rx%3D%22192%22%20ry%3D%22102%22%2F%3E%3Cpath%20fill%3D%22%23cecfcf%22%20d%3D%22M150%20125h21v47h-21z%22%2F%3E%3Cellipse%20fill%3D%22%23ffb8dd%22%20cx%3D%22243%22%20cy%3D%2237%22%20rx%3D%2268%22%20ry%3D%2211%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Open End Flat Barrier Pouches 2×3 S-18136 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c7c7c7%22%20cx%3D%22122%22%20cy%3D%22140%22%20rx%3D%2243%22%20ry%3D%2238%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22110%22%20cy%3D%2242%22%20rx%3D%22255%22%20ry%3D%2260%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-.16572%2046.09747%20-178.93344%20-.64328%20126.6%20223.3)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22235%22%20cy%3D%22136%22%20rx%3D%2272%22%20ry%3D%22255%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 20×29 S-23408 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c5c5c5%22%20cx%3D%22138%22%20cy%3D%225%22%20rx%3D%22255%22%20ry%3D%229%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M257.5%20267.5H2.5v-255h255z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22130%22%20cy%3D%22142%22%20rx%3D%22255%22%20ry%3D%22129%22%2F%3E%3Cellipse%20fill%3D%22%23e5e5e5%22%20cx%3D%221%22%20cy%3D%2213%22%20rx%3D%22255%22%20ry%3D%221%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 18×24 S-22298 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c6c6c6%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(.6%20-305.2%209720.2)%20scale(229.17029%2017.92206)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22115%22%20cy%3D%22186%22%20rx%3D%22160%22%20ry%3D%22160%22%2F%3E%3Cellipse%20fill%3D%22%23ccc%22%20cx%3D%22122%22%20cy%3D%2224%22%20rx%3D%2236%22%20ry%3D%224%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20d%3D%22M-16%2030l287-7-57%20248z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 12×18 S-18134 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c6c6c6%22%20cx%3D%22127%22%20cy%3D%2211%22%20rx%3D%22255%22%20ry%3D%2216%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(90.5%20-10%20139.3)%20scale(123.00504%20254.99999)%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22matrix(-14.0587%20114.49898%20-253.09927%20-31.07668%20130.8%20146.7)%22%2F%3E%3Cpath%20fill%3D%22%23dfdfdf%22%20d%3D%22M0%200h256v27H0z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 10×16 S-24087 Dieline

$0.00 Add to cart -

%27%20fill-opacity%3D%27.5%27%3E%3Cellipse%20fill%3D%22%23c8c8c8%22%20fill-opacity%3D%22.5%22%20rx%3D%221%22%20ry%3D%221%22%20transform%3D%22rotate(-179.1%2056.1%206.4)%20scale(225.31504%2028.60737)%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M0%2048h298.8v259H0z%22%2F%3E%3Cpath%20fill%3D%22%23cacaca%22%20fill-opacity%3D%22.5%22%20d%3D%22M114.3%2041.6h62v7h-62z%22%2F%3E%3Cpath%20fill%3D%22%23fff%22%20fill-opacity%3D%22.5%22%20d%3D%22M306.5%20318.2L312%2031.7l-38.5%201.1-291.7%20236z%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 10×12 S-21994 Dieline

$0.00 Add to cart -

%22%20transform%3D%22translate(.6%20.6)%20scale(1.17188)%22%20fill-opacity%3D%22.5%22%3E%3Cellipse%20fill%3D%22%23c7c7c7%22%20cx%3D%22127%22%20cy%3D%2216%22%20rx%3D%22255%22%20ry%3D%2219%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22127%22%20cy%3D%22186%22%20rx%3D%22146%22%20ry%3D%22146%22%2F%3E%3Cpath%20fill%3D%22%23d1d1d1%22%20d%3D%22M128%2049l30-18-80%203z%22%2F%3E%3Cellipse%20fill%3D%22%23fff%22%20cx%3D%22224%22%20cy%3D%2267%22%20rx%3D%22123%22%20ry%3D%2234%22%2F%3E%3C%2Fg%3E%3C%2Fsvg%3E)

Metallized 3 Seal Flat Barrier Pouches 8×10 S-16896 Dieline

$0.00 Add to cart

Tags