No products in the cart.

Fin Seal vs Lap Seal vs Edge Weld Seal

What are the Different Types of Heat Seals?

In the world of flexible packaging, there are several types of heat sealing techniques to choose from. Deciding which type of heat sealing process is suitable for your application can only be determined on a case-by-case basis, as it depends on a variety of factors. Fortunately, CarePac can help you choose the heat seal method (or methods) that are right for your custom flexible packaging.

Selecting the right type of heat seal is imperative, as the bag's seal (and seal strength) is what provides a moisture barrier and helps protect sensitive products from product contamination. For the gold standard in heat sealing technology, look no further than CarePac.

In this blog, we'll explore the three common types of heat seal techniques that are suitable for most situations: lap seal, fin seal, and edge weld seal.

What is Fin Seal Heat Sealing?

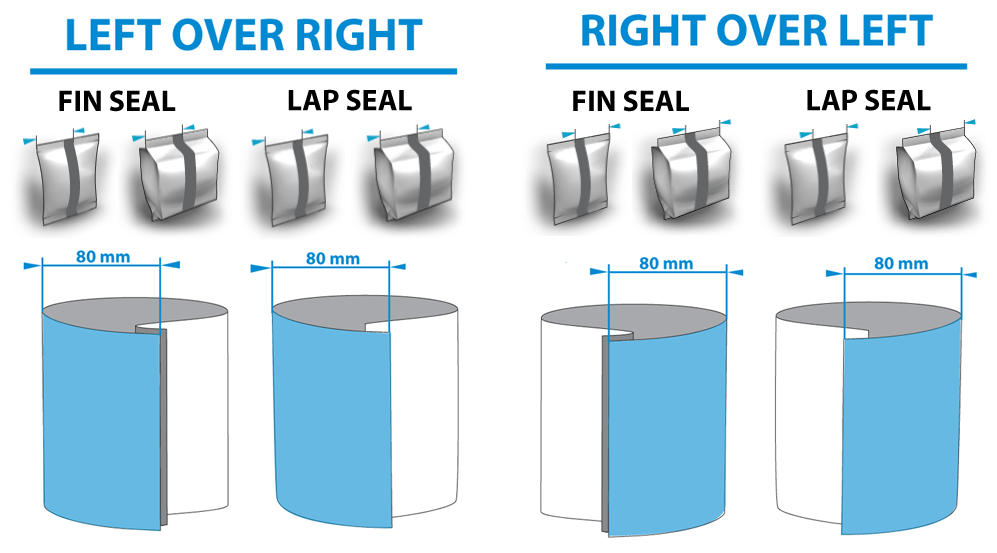

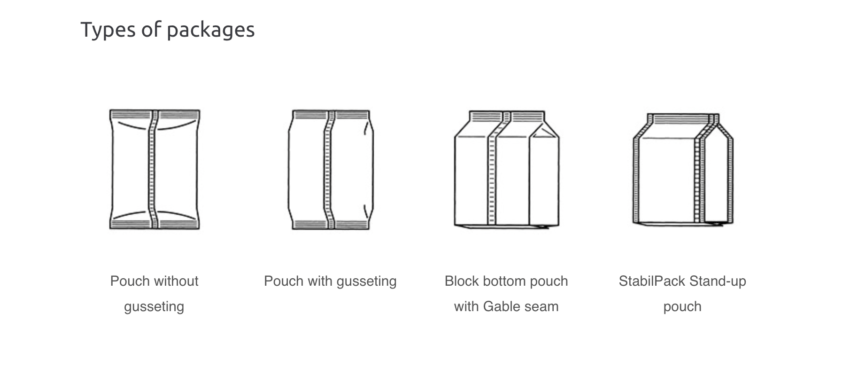

A fin seal brings the film edges together inside a form tube, and then seals the inner surfaces. Simply put, a fin seal seals the inside of the bag material to the inside of the bag material. This creates a tight bond along the back of a package, which keeps the products fresh and stable on the shelf. Fin seal bags are suitable to package candy bars, baseball cards, snacks, potato chips, and pizza, they're popular for their sleek appearance and versatility.

Some drawbacks of a fin heat seal are that they're less puncture resistant than some other types of heat sealing techniques or thermoplastic materials, due to their lower seal strength. Additionally, they use more material than lap seals, meaning there's less cost effective than other options, and have a relatively short shelf life (9-12 months), which may be an issue for small businesses. But, if your facility is set up for continuous sealing and packaging, the seal integrity offered by fin seal heat sealing may be a good choice for you.

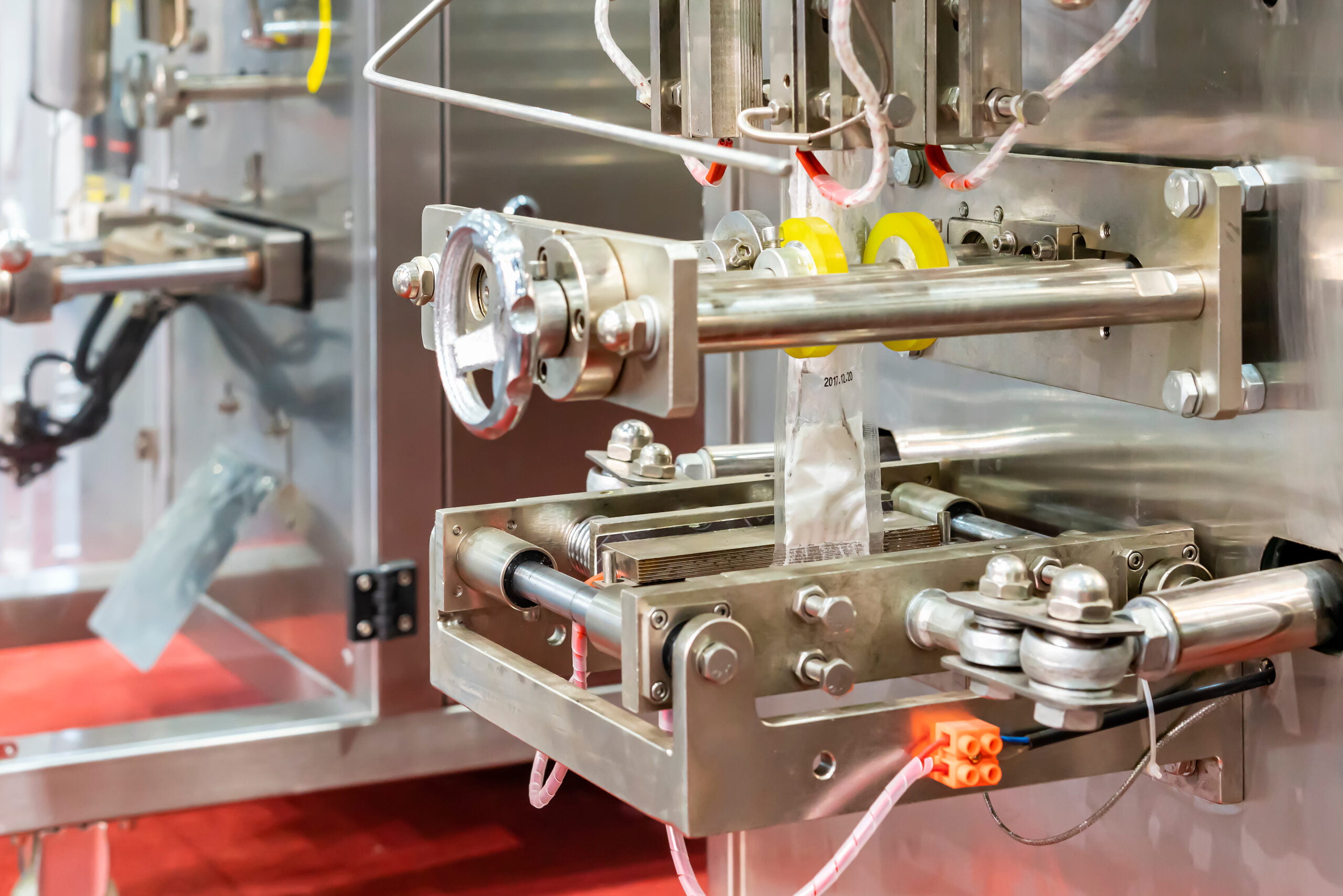

Fin seals can be implemented using a form-fill machine and/or a heat sealing machine. Simply stretch the film onto a roll and them form it into a tube, seal the sides together to create a fin seal, and then seal the top and the bottom of the tube together to create a pouch or mylar bag.

What is a Lap Seal Heat Seal?

In lap heat sealing, the two edges of the film overlap and are sealed together, with the back of the top side sealing to the front of the bottom side. This heat sealing technique produces a very robust seal along the side of the packaging, protecting the contents inside from external elements like moisture, oxygen, and physical damage.

Commonly used for food products like chips, cookies, and pet food, this heat sealing technique is a great choice if durability and preservation are required. This type of seal requires that both surfaces being fused together be constructed from thermoplastic materials.

What is the Edge Weld Heat Sealing Process?

The edge seal heat sealing technology provides an airtight and watertight enclosure. This protects the contents inside the bag from moisture, dust, and other environmental hazards. Using an edge heat sealer provides many advantages, including:

- Seal strength eliminates the potential for contaminates to enter the heat sealed packaging

- The consistent seals improve the strength of the box or pouch

- The seal quality improved the insulating properties of the package, by trapping the cold air inside the walls of the box. This helps keep the contents inside at a near constant temperature.

As you can see, if you require a bit more temperature control for your product (i.e., you're packaging things like chocolate that can't be exposed to high heat levels or they'll melt), a polyethylene bag with an edge seal has many advantages.

Choosing the Right Heat Sealer for Your Packaging

As mentioned, selecting the right heating element and heat sealer methods for your packaging depends on several factors. Will you be packaging something with a shorter shelf life, like food or snacks? Does your facility go through many bags in a month, or is there dwell time and the expiration date of the bags a major concern? What about the temperature inside the sealed bags? How about materials -- polyethylene or plastic film? Something thicker? Do you need an adhesive?

As you can see, there are a lot of things to think about when selecting materials and a heat sealer process. Fortunately, we can help.

CarePac: Your Partner in Packaging

With decades of experience in the packaging industry, we can help you select the right heat sealer technique for your unique application. Whether you’re ordering standard-sized heat sealer rolls or are looking for something more customizable, CarePac can help support all your packaging needs.

No job is too large or too small for our team of professionals. Have questions? Want to get started? Get a Quick Quote, order samples, or contact us today for more information.

Heat Seal Types: FAQs

From seal bars and heating elements to seal jaws and heated tooling, here are some common questions we receive about the complexities of heat sealing:

What are impulse heat sealers?

Impulse heat sealers are powered tools that use a heating element (often an electric current) to melt plastic or another material to create permanent seals. This process will apply heat so the melted plastic will cool down and act as an adhesive.

What is constant heat sealing?

Constant heat sealing, also known as continuous heat sealers, is a heat sealer method that passes the materials under a set of heated jaws that maintain a constant temperature.

What is direct contact thermal sealing?

Direct heat sealers are able to maintain constant heat in both seal jaws. Its advantages include a smaller initial investment and its cost effectiveness when compared to other heat sealer techniques.

What is a sealing bar?

Sealing bars are used to properly seal two parts of a package in a high temperature environment.