No products in the cart.

Gloss Lamination vs Matte Lamination: Key Differences Explained

Introduction to Lamination in Packaging

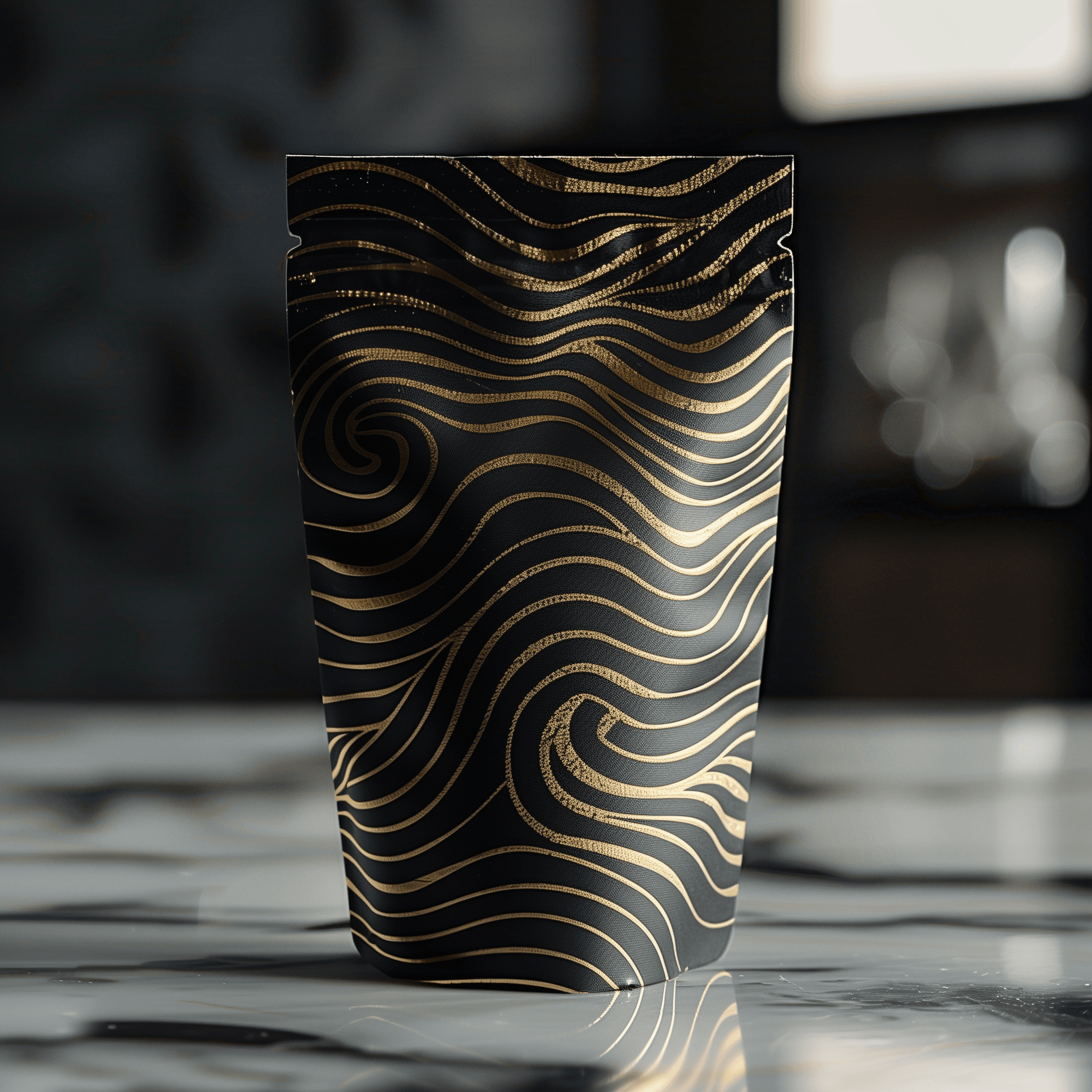

When people think about a product's packaging, elements like logo placement, size, and color may come to mind. But did you know that even the smallest details, like a bags protective layer and how it reflects light also have a big impact on its visual appeal?

Choosing the right lamination is crucial to your print project -- it draws your customer's attention to the printed items, whether it be a stand up pouch, menu cards, or research posters, and can also act as a layer of much-needed protection against dust and damage, particularly if spot UV elements are incorporated into the packaging.

Here, we'll discuss matte lamination, glossy lamination, their key differences, and how to use lamination to create a sophisticated and understated look. Whether you opt for matt lamination with spot UV or opt for a glossy surface instead, we're here to help you choose the right type of film lamination for your needs. Read on to learn more about matte and gloss lamination.

What is Matte Lamination?

The most basic way to describe matte lamination is muted and flat. If you choose to incorporate matte laminates into your packaging or printed materials, it'll give it a silky smooth and non-reflective finish. Matte laminate is a great choice for many different types of packaging, as it reduces glare and ensures your package design is visible from every angle. It also hides minor imperfections and provides a tactile feel to the package, making it more interesting to hold. Often used for book covers and cosmetics packaging, matte lamination will hide smudges and fingerprints while creating a sophisticated finish.

Limitations of Matte Lamination

Of course, matte lamination does have some drawbacks. It can make colors seem dull and washed out, and scratches more easily than gloss lamination.

What is Gloss Lamination?

Unlike matte lamination, glossy lamination has a lustrous look. Think of gloss laminate like a clear coat on your freshly washed car or recently painted nails: it adds a touch of vibrancy and provides a protective layer. One of the biggest benefits gloss lamination offers is it makes pictures and images appear brighter and more vivid. If you're trying to wow your customers with bright colors and zany designs and are worried about the wear and tear of your packaging, you can't go wrong with the glossy surfaces created by gloss lamination.

Limitations of Gloss Lamination

Now for the drawbacks. The main drawback of gloss laminate is that it can create a glare, especially when viewed in direct lighting. This can make it difficult for your customers to read text or see photographs. Additionally, fingerprints and smudges are more obvious on gloss lamination than on printed material with a matte finish.

Matte vs Gloss Lamination: Key Differences

Here's a quick breakdown of matte and gloss lamination, presented in an easy-to-view manner. When comparing matte vs high gloss laminate, the differences can be broken down into four categories: protection, laminate appearance, glare, and the ink receptiveness of the materials.

Gloss Laminate: A Quick View

- Protection- Scratches and scuffs are more visible on the glossy surfaces produced by gloss lamination. It is simply not as durable as soft touch lamination.

- Appearance- Gloss lamination produces a very shiny, high-impact result. If you're looking for a shiny appearance, gloss lamination is the perfect lamination for your packaging.

- Glare- Since light reflects off gloss lamination, it produces a lot of glare, which can be problematic depending on its use. If the intended purpose of the package or product is to be read and it will be seen in direct or extreme lighting conditions, you may want to opt for matte lamination materials instead of gloss

- Ink Receptiveness- Gloss lamination is difficult to write over, even with a Sharpie or permanent marker.

Matte Laminate: A Quick View

- Protection- Matte lamination resists fingerprints, scuffs, scratches, and dirt better than glossy film packaging does. If you're concerned about dust, you can't go wrong with matte.

- Appearance- Creates a soft, low-key final result. A matte finish creates a higher perception of quality, and is often used for high-quality cosmetics or in a book cover. If you need a smooth finish and an eye catching appearance, this is one of the best lamination types.

- Glare- Matte lamination does not produce any glare. If your package will be handled in direct light, this lamination type is your best choice.

- Ink Receptiveness- You can easily write over this thin film lamination.

How to Choose Between Matte vs Gloss Lamination

Choosing the right type of lamination ultimately depends on your specific use case. Are you in the beauty or cosmetics industry? If so, you can't go wrong with the soft touch lamination provided by matte lamination. Does your packaging contain a lot of colors and bright designs? You'll probably fare better with an attention grabbing glossy label.

Each has its advantages and disadvantages, and it can be difficult for our clients to choose on their own. Fortunately, we'll assist you in finding the sweet spot between impressing your customers and protecting what's inside the packaging.

Connect with us today to get your packaging project started! We'll help support all your printing needs, no matter how large or small.