No products in the cart.

Smart Cost Reduction Strategies for High-MOQ Packaging

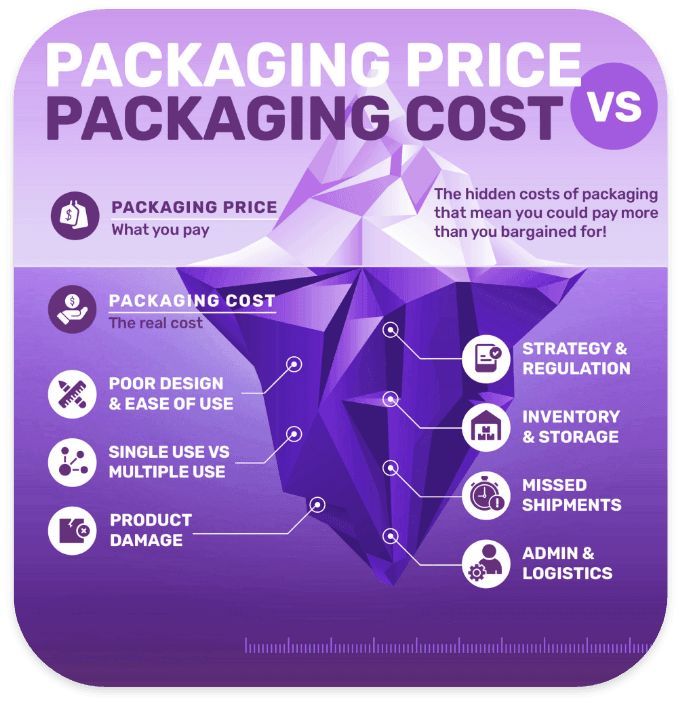

With talks of a recession looming and prices for virtually everything reaching astronomical highs, many organizations are looking into cost savings measures, including how to reduce packaging costs and shipping costs. From making an effort to reduce labor costs to removing inefficient manufacturing models, there are quite a few ways for companies of all sizes to improve their warehouse operations and packaging process.

If you're looking for ways to reduce expenses and shipping costs, one area to explore is your packaging strategy, including your current packaging expenses and packaging process. From packaging materials to your shipping operations, you can experience significant savings in this area. In this blog, we'll explore the challenges of high-MOQ packaging costs, and some proven strategies for reducing packing costs and material waste.

The Challenge of High-MOQ Packaging Costs

Minimum order quantity (MOQ) packaging has many challenges. First, you need to commit to a certain packaging threshold before you can even move to the next step of the packaging process: product packaging design. Next, you need to figure out how to maximize packing space in your warehouse so you aren't wasting money on warehouse space you don't actually need.

Fortunately, CarePac has expertise in providing cost-effective solutions for businesses with high MOQ needs. If you need high volumes of packaging, we can offer significant cost savings by looking at things like packaging materials and design and customization costs.

Understanding the Cost Drivers in High-MOQ Packaging

The main cost drivers of high-MOQ packaging is packaging materials and the cost of designing custom packaging. Here, we'll discuss how each impacts your packaging strategy a bit more in depth.

Packaging Materials & Their Impact on Costs

Materials play a pivotal role in determining overall packaging expenses, as they directly affect both the production costs and the long-term sustainability of packaging solutions. The cost of raw materials can vary significantly depending on their type and quality, and different materials require specific processing methods that may be more (or less) expensive than others.

Here are some of the key material packaging strategy for reducing cost of the packaging.

Reduce packaging materials by reducing thickness: Thickness of your film can directly corollate to direct costs and indirect costs like transportation costs because thicker material is heavier. A bit of time and money spent doing R&D on what the minimum thickness you need is, can save you thousands of dollars over time. Have you researched if a 3mil film can work in your application as well as 4 mil film? Luckily with CarePac's prototyping services you can test out actual bags before major orders.

Change lamination structure: Sometimes the solution is not to reduce thickness, but to change the lamination structure. Incorporating a variation in the material used can reduce costs without sacrificing performance. A common source is by adding or removing coatings, like EVOH, PVDC, and more.

It's important to balance the above with the durability of the packaging. Durable packaging holds up better during the shipping processes, so you can minimize waste from having to throw away your product if it opens or spoils during shipping. Using recycled materials, like corrugated cardboard or mushroom packaging that reduce your carbon footprint can also have an impact on your costs.

Design and Customization Costs

Design features and customization play a significant role in influencing packaging costs, as they impact the complexity, material usage, manufacturing processes, and the overall efficiency of packaging. The more complex your packaging design is, the more expensive it will be to produce. While customization and branding is important within the packaging industry, it does increase the cost of packaging. Next, using bulky packaging that isn't made from sustainable packaging materials can increase your waste management costs.

If you aren't thinking about the complexity of your packaging solutions and how the bulkiness of your product packaging might be increasing shipping costs, now is the time to start considering the impact of these on your bottom line.

Proven Strategies to Reduce Packaging Cost

If you're concerned about high packaging costs, there are several things you can do to improve your packaging operations. In this section, we'll discuss ways to reduce packaging costs and shipping expenses with better product packaging solutions.

Optimize Packaging Specifications

Your product packaging should be perfectly sized for the product it's intended to contain. You shouldn't be wasting money on high material costs by using more packaging than you really need. At the same time, though, you shouldn't be having to throw away perfectly good corrugated cardboard boxes or bubble wrap because it's too small for your product. A custom-fit, right-sized package helps you save money on shipping costs, too.

The benefits of optimizing packaging specifications trickles down to your customers, too. They'll appreciate packaging that fits the product well, and won't have to deal with the frustration of poor packaging materials that impact the quality and functionality of their product.

Streamline Production and Supply Chain Management

If you're looking to reduce packaging cost, collaborating with collaborators is a critical strategy. It can help you reduce lead times, lower costs, and can ultimately lead to improved customer satisfaction. Work with your partners to forecast your company's needs and produce packaging materials in advance. Improving your communication can help prevent out-of-stock items, rush orders, or last minute production needs that can cause the cost of packaging to skyrocket.

At the end of the day, streamlining production and supply chain management can help businesses just like yours secure better pricing, make lead times more favorable, and can help reduce the risks of delays or fluctuations in price.

Leverage Cost-Effective Printing Solutions

When trying to reduce packaging costs, businesses must weigh the pros and cons of digital printing and plate printing. Both methods have their unique advantages and disadvantages, especially when it comes to the per-unit-cost of your heavy, mid, and lightweight packaging.

Digital Printing

Digital printing uses digital files to print onto a variety of materials, including eco-friendly and sustainable materials. It has lower setup costs, more flexibility and customization, a faster turnaround, and typically has low MOQs. It does have some disadvantages, though, namely it has a higher per-unit cost for large quantities, has limited material options, and a lower print quality. It's best for short runs or projects where quick turnarounds and customization is important.

Plate Printing

Plate printing is a more traditional printing process for the packaging industry, and involves transferring ink from a metal plate onto the printing surface. It's the most common printing method for high-volume materials, like books made from recycled paper and plastic bags. Its advantages include a lower cost per unit at high volumes and a higher print quality, making it ideal for larger runs. It does have higher set up costs, longer lead times, and less flexibility, but these higher packing costs are offset by its many advantages for high-MOQ packaging.

The Role of Shipping and Fulfillment in Cost Reduction

Shipping expenses and fulfillment costs play a crucial role in the cost of your packaging solutions. By making your shipping and fulfillment processes more streamlined, you can reduce both labor and material costs. Here, we'll explore how you can reduce shipping costs via packaging optimization and how you can cut costs on warehouse space by keeping a better eye on your inventory.

Reduce Shipping Costs Through Optimized Packaging Design

We don't have to tell you that using proper packaging like lightweight packaging costs less than big and bulky packaging. Lighter packaging reduces the weight of your shipments, allowing you to reduce shipping costs throughout your packaging supply chain. Compact packaging also reduces the amount of money you need to spend on warehouse space, which is one cost saving measure that's often overlooked. Finally, optimized packaging operations means spending less money on filler materials, helping you make sustainable packaging and shipping processes the core of your focus.

Warehouse Efficiency for High-MOQ Inventory

One of the best ways to reduce packaging costs is to look at your warehouse space and related labor costs. Stacking inventory strategically is one packaging strategy that can help you reduce costs and enhance your shipping operations. Utilizing proper storage systems, like shelving units or customized racks, can help keep your inventory (i.e., plastic packaging, eco friendly packaging, and stuffing materials) organized and always within reach.

Regularly rotating your stock and investing in automated packaging lines can reduce costs across the board. The time you spend improving your warehouse efficiency can result in other improvements, including improving your shipping efficiency, and reducing your transportation costs.

Why CarePac is the Ideal Partner for High-MOQ Packaging

Partnering with CarePac for your high-MOQ packaging is one of the best steps you can take when it comes to reducing waste. We are able to offer competitive pricing for large orders by leveraging our strong packaging supplier relationships and eco friendly practices. We have fast turnaround times, which can help you meet your high-volume demands with ease. Finally, we prioritize using eco-friendly and sustainable packaging solutions.

Through these strategies, we can provide a comprehensive, cost-effective solution for businesses needing high-MOQ inventory, ensuring both operational efficiency and environmental responsibility. Contact us today!

Let's Get Started

Made In

The USA

Full Pouch

Customization