No products in the cart.

Flexographic Printing: All About the Flexography Printing Method

If you’ve project managed a large-scale commercial printing project before, you’re probably already familiar with popular forms of printing, like digital and rotogravure printing. But did you know there’s a third option you can choose from? Flexographic printing is a modern, high-speed printing method that’s suitable for a variety of applications, but particularly for label printing on kraft paper bags.

What is the flexographic printing process?

Modern Flexographic presses are cost-efficient, and render high-quality printing technique. Some common household products that are typically printed on flexographic presses include ice cream cartons, paper shopping bags, gift wrap, envelopes, and disposable plates and cups, in other words, many of the products you see lining the shelves in a grocery store. Flexographic printing of flexible pouches is generally reserved for cases such as printing compostable Kraft exterior pouches, as flexographic printing is able to handle the rough untreated exterior Kraft paper especially when compared to rotogravure printing, which requires a more processed substrate.

How does printing with a flexographic printing press work?

Flexographic printing is actually a pretty easy process to understand, as it comes down to three main steps: art and design, material selection, and the actual printing. Here’s a little more info about each step of the CarePac flexographic printing process.

Step 1: Art and design

Need full art and design services? Have a very specific look in mind for your bags? No problem. We love complex projects and are happy to provide brand design services to help you create the branded packaging your product deserves. We'll get your product to stand out from the crowd! Plus, the bags will be designed to your own specifications! As an added benefit, we’ll keep your designs on file so you’ll only have to design them once.

Step 2: Material selection

Once you’ve settled on a design, the next step is to select a bag material. Fortunately, CarePac has a variety of materials to choose from. As we discuss further on, we typically find that flexo printing is best used for compostable projects, or projects that are wanting a "natural" look or feel with direct printing on Rice paper, White paper, or brown Kraft Paper. Thus we usually designate flexographic printing for direct surface printing kraft paper or rice paper pouches.

Step 3: Print your bags

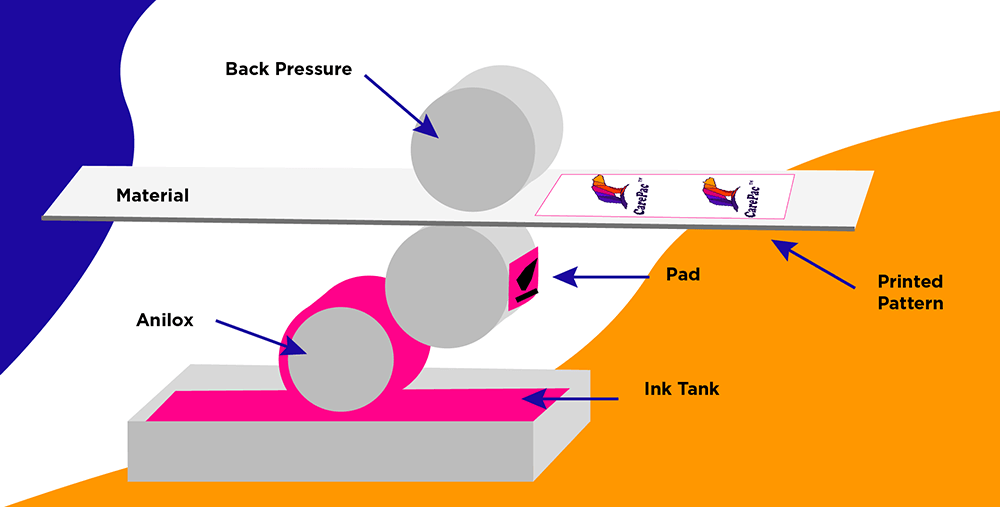

Now, it’s time to print. During this phase, a roll of substrate is fed directly into the printing machine where ink is transferred onto the roll. Once the ink color is transferred to the material, the material is sent through roller-less and plate-less sections to dry the ink. The final step is the outfeed and rewind, where the material is rolled up again in preparation of cutting. It might sound complex, but we’ve been doing this for years and we have the machinery and plenty of expertise!

Flexography makes your project more economical

Flexographic printing is great for production quantity orders (5,000+ bags) just like rotogravure printing, you can make your project timeline even faster by opting for one of CarePac's expedited lead time menu options and UV flexography. UV flexography uses inks that are curable with UV light, meaning they’ll dry much faster than projects that use standard drying methods. In addition to faster drying times and a quicker production time, UV curable ink is also VOC free and offers superior print quality on kraft paper.

For more information about our UV ink options, ask about UV flexography during the design stage.

Flexographic printing applications

As mentioned above, virtually any printing project can be printing flexographically. Although this is the case, here at CarePac we reserve flexographic printing for surface printing of papers, generally for compostable pouch applications, or any lamination involving like rice paper or kraft paper bags. By flexo surface printing these materials your pouch can have a more natural look, and more of the rough paper texture can be felt by the customer when the touch your pouch.

One important thing to note is that you should avoid incorporating plastics into your bag if you want them to be compostable. If you’re searching for an eco-friendly option, consider bio-plastic interior liners so they can still be composted.

Flexographic printing plates vs digital

So, what’s the difference between the flexographic technique and digital offset printing, and which is the right choice for your print job? Here’s a quick breakdown of the pros and cons of each printer method so you can make an informed decision. Still have questions? We’re here to help you decide.

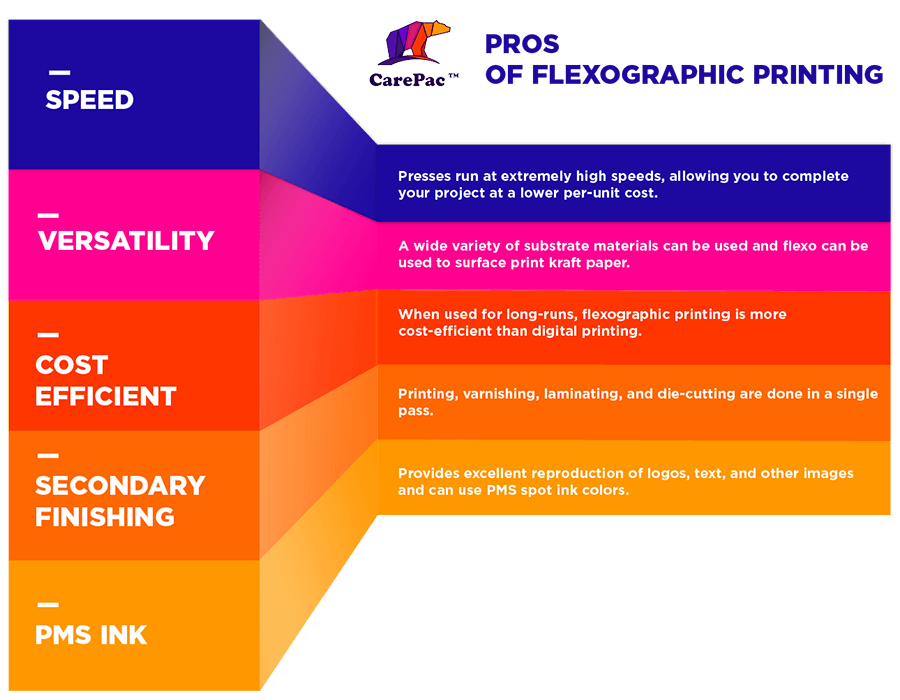

Pros and cons of flexographic printing

Flexo printing adapts well to different materials and can use a wide range of inks, like water-based flexographic printing inks rather than oil-based inks, like those used in offset printing. Other benefits include:

Of course, there are some cons to point out, too.

First, a flexographic printing press is complex and requires more setup for each print run, which makes it more suitable for orders of 5,000 or more pouches. Additionally, each color printed requires its own flexible printing plate, which can incur some initial setup and platemaking cost. Finally flexographic is slightly less effective at printing CMYK images than digital or rotogravure. All three of these can mean a more costly project than if you opted for digital printing.

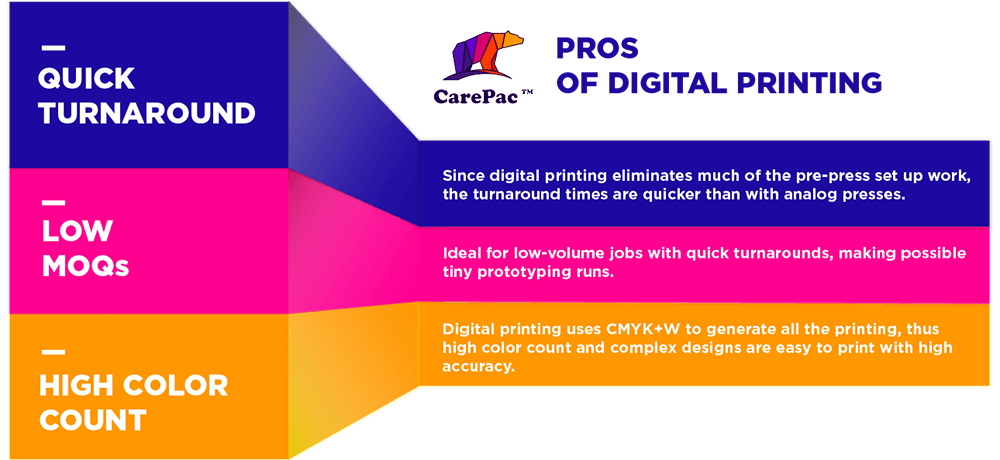

Pros and cons of digital printing

Like flexo printing, digital printing has its own applications and pros and cons. Here are some of the benefits of digital printing:

Like flexographic printing, digital printing also has some unique disadvantages.

First cost, digital printing typically yields a higher per-unit cost at the same production quantity than flexographic or rotogravure.

Second ink, digital printing inks fade quicker on an image than flexographic inks, digital ink is less opaque, and digital printing cannot 100% replicate PMS spot colors.

Third consistency between runs, digital printing can be prone to more color variation between print runs.

Can flexographically printed bags be customized?

Yes! CarePac makes customized flexible packaging, and that includes packaging that’s printed with a flexographic printing press. Our design consultants will help bring your ideas to life -- whether it’s adding a composite of your log or special features, like a zipper, hang-hole, or rounded corners.

Want a bag that will stand up on a shelf? We can do that! What about containers that have a degassing valve for coffee beans? Yep, we can do that, too! How about a bag that zips, has holographic accents, or is printing with your brand’s special colors? Yes, yes, and yes! We can do all of it, simply contact us today to get your design project started.

Flexographic printing FAQ

Q: What is the Minimum order quantity for flexographic printing?

The MOQ on flexographic printed pouches is typically 5,000 bags per sku (design).

Q: Is flexographic printing as high quality as digital printing?

It depends on what you are printing, flexographic printing technology and the flexographic printing industry can typically out-perform digital printing on long print runs, Kraft paper pouches, and spot color prints. Digital printing can outperform for small quantity orders, printing photographs on the pouches, and complex or poorly trapped art.

Q: What are some of the drawbacks of flexographic printing?

What it’s not great at is extremely fine detail or 4-color process. Flexo mostly uses photopolymer plates, which are thin, flexible plates made of photoreactive plastic. They are exposed to light through a film negative or written directly onto the flexographic printing plates with a laser. This means that to achieve lighter areas, the polymer must be etched away more in those areas, which can cause some instability in the image. Flexo inks and solvents also tend to be thinner, making it more difficult to control the behavior of the line-screen on the substrate when printing 4-color process.

Q: Can Flexographic printing be used to print plastics like PET and MOPP exterior pouches?

Yes flexography could be used for printing "normal" plastic pouches, but typically rotogravure will yield a higher result. Flexographic presses run hot, as hot as 350F which can create trouble when printing thin film pouch skins like 1/2 mil PET or MOPP material. An Intaglio printing method like Rotogravure or digital printing is more suited for these types of materials.

Q: What materials does CarePac typically have Flexo printed?

The two most common materials that we would use flexographic printing for are CareCompost-KP, CareKraft-KVP.

Tips for becoming an environmentally-friendly company

Many companies choose flexographic printing on their kraft paper bags because it’s the most eco-friendly option available on the market. In addition to selecting paper bags and opting for flexographic printing, there are a few other ways you can become a more eco-friendly brand, including:

Avoid excessive packaging. Is it necessary to package something the size of a pen in an oversized package? No. Do you really have to include layers and layers of tissue paper or bubble wrap in a box that isn’t transporting something fragile? Definitely not. These are the questions you should be asking yourself before you ship. When in doubt, always opt for the smaller box.

Greenwashing. Greenwashing is the term used for companies that deceptively try to persuade the public to believe its products and policies are environmentally friendly when they really aren’t. Nothing is worse than a company that claims its eco-friendly but isn’t, so if you’re not being environmentally friendly right now don’t bother saying you are (at least until you are!) Basically, your commitment to the environment must go beyond just your image!

Not shipping items together. Another common practice, especially popular with Amazon, is to ship items one by one as they become available in the warehouse instead of waiting until the entire order is complete. At minimum, give consumers the option to have all their items sent in one box. You’d be surprised how often consumers are willing to wait if given the option.

As you can see, being eco-friendly is more than just a catchphrase. It’s an ethos. If you’re ready to walk the walk, we can help you select green packaging options.