No products in the cart.

Gloss is the default finish for barrier pouches

Most plastics have a default gloss finish. Glossy stand up barrier pouches can be found being used in almost every industry and for a vast array of consumer goods. Whether for food pouches or chips packaging, to industrial use bags and fertilizer bags, these barrier bags are a great choice.

Advantages of a glossy finish

Easy to read, and allows clear windows

If you want your product to be seen from the outside through a clear viewing window then a glossy finish on our window stand-up pouches is a must. While you can use a spot matte finish the window itself will need to be glossy because matte coatings and finishes create a frosted window where you cannot clearly see the contents.

Harder to scuff

Unlike matte finishes, glossy finishes do not scratch or scuff easily. Gloss is a very durable finish. One of the best barrier pouches on the market. Plus, these panel stand-up pouches are better than paper.

Esthetic

Esthetic, likely the most important reason to pick a glossy finish is because it is the aesthetic you are looking for. Glossy style plastic bag finishes helps increase the vibrancy of the colors used in your design. These stand-up food pouches are great for private label products, wine gift boxes, and wine gift bags, and will wow your customers more than paper or other food packaging supplies.

MATTE VS GLOSS LAMINATION

Below are two examples using of clear films used to make printed pouches. On the left is a matte film, and on the right is a glossy film.

Why CarePac?

We Save You Money

We have many different flexible packaging solutions and stand up pouches for budgets of all sizes. Now you can compete with the largest brands in the industry at a price that works for your business. Our top stand up pouches are beautiful and sturdy.

Fast Lead Times

We offer some of the fastest lead times in the packaging industry. Expedited lead times for paper, digital and plate printing come in at 4 weeks and 5 weeks respectively.

Lock in Freshness and Flavor

Packaging your product in high quality flexible packaging keeps your products fresher for longer and make storage simple for the end user.

Low Minimum Order Quantities

Our MOQs can't be beat. Print and customize as few as 5,000 bags.

FDA Approved

All of our packaging is FDA approved, and free of TSE, BPA and Sulfer & Phthalates. See why we're a favorite in the industry?

Art & Design Services

Glossy finishes were made for branding. Do you need a logo, design or labels? No problem. We provide brand design services to help you create the branded packaging your product deserves. We'll get your product to stand out from the crowd!

What is Gloss Packaging?

It's a flexible barrier pouches with elegant and glossy finishing.

There are two types of finishing for our plain and colored stand-up pouches: coating and lamination. A lamination uses a material that covers the entire exterior surface of the bag. Typically laminations are not required for glossy pouches because most of the standard print layer materials are already glossy. Matte Laminations, are often used when a matte finish is required for the entire bag. Coatings are another way to apply finishes. Coatings have some technical differences in how they perform, but are also great for apply combination finishes (spot finishes), where one area of the bag is glossy and another area of the bag is matte.

Gloss

Matte

Spot Matte (plate only)

Soft Touch (plate only)

Custom Gloss Finish FAQs

At CarePac, we get a lot of questions about finishes. Here are some of the most popular FAQs we receive. Don’t see your question answered? Contact us today!

Are there different levels of gloss available?

Generally there is only one “level” of gloss, we do offer a ultra-clear material that can provide both a gloss finish and a very low haze level for clear viewing windows. this material can be combined with a matte coating to provide a very glossy area, with other areas of the pouch matte.

Can a pouch have both glossy areas and matte areas?

Yes, this is commonly referred to a as Spot UV, Spot Gloss, or Spot Matte. A varnish is applied to the areas based on your finish preference. A mixed finish can be very striking, helping certain elements of the design really pop helping your product stand out on the shelf.

I want a viewing window on the front panel of my stand-up food pouches, does it have to be glossy?

No it does not have to be glossy, but if your window is not gloss, then it will have a frosted appearance. Frosted windows can provide a idea of what is inside the pouch, but for maximum visibility you'll want to incorporate a glossy window.

What is more popular Glossy stand up pouches or matte ones?

Gloss finishes are the most popular pouch finish for a variety of products.

Are "Crystal clear" pouches glossy?

No, crystal clear, ultra clear or high clarity refers to the base films haze level but not the finish. Typically a ultra clear pouch will be glossy, but it can have matte coating finishes applied.

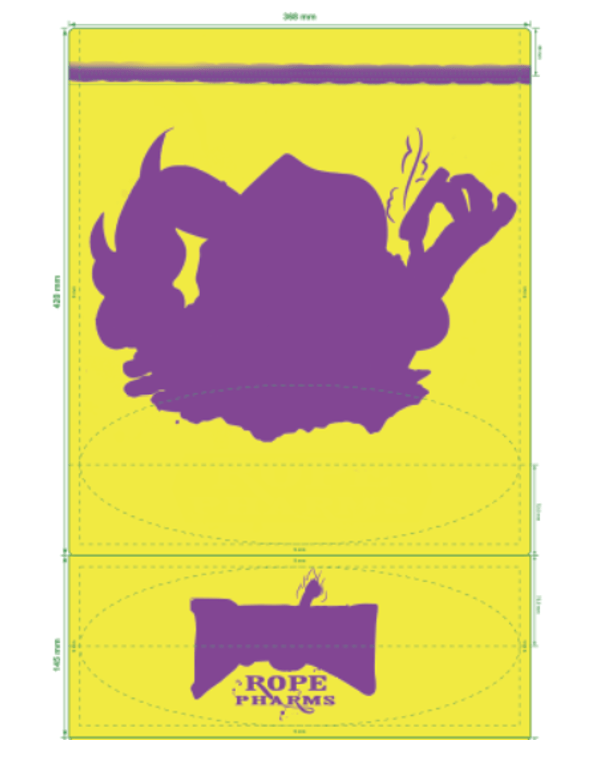

How do I designate a pouch finish on my dielines?

The best way to designate finishes is using finish mapping, a finish map is a separate layer on your AI file that uses two contrasting colors to designate gloss and matte areas. In the example below the areas that are matte are in Yellow, and the areas intended to be gloss are in purple.

Do PMS colors shift when used on a glossy finish stand up pouch?

PMS colors are pantone matching colors, which are keyed to a paper substrate under specific lighting conditions either D50 light which simulates Daylight at a color temperature of 5,000K or D65 which is simulating Daylight at a 6,000K temperature. Pantone colors which will most closely resemble when used on your plastic bag are the “C” deck colors. You can by a “C” deck on Pantone’s website https://www.pantone.com/