Subtotal: $19.99

Pet/NYLON/PE Bags | Pet/NYLON/PE Barrier Bags & Flexible Packaging

What Everyone Ought to Know about PET/NYLON/PE

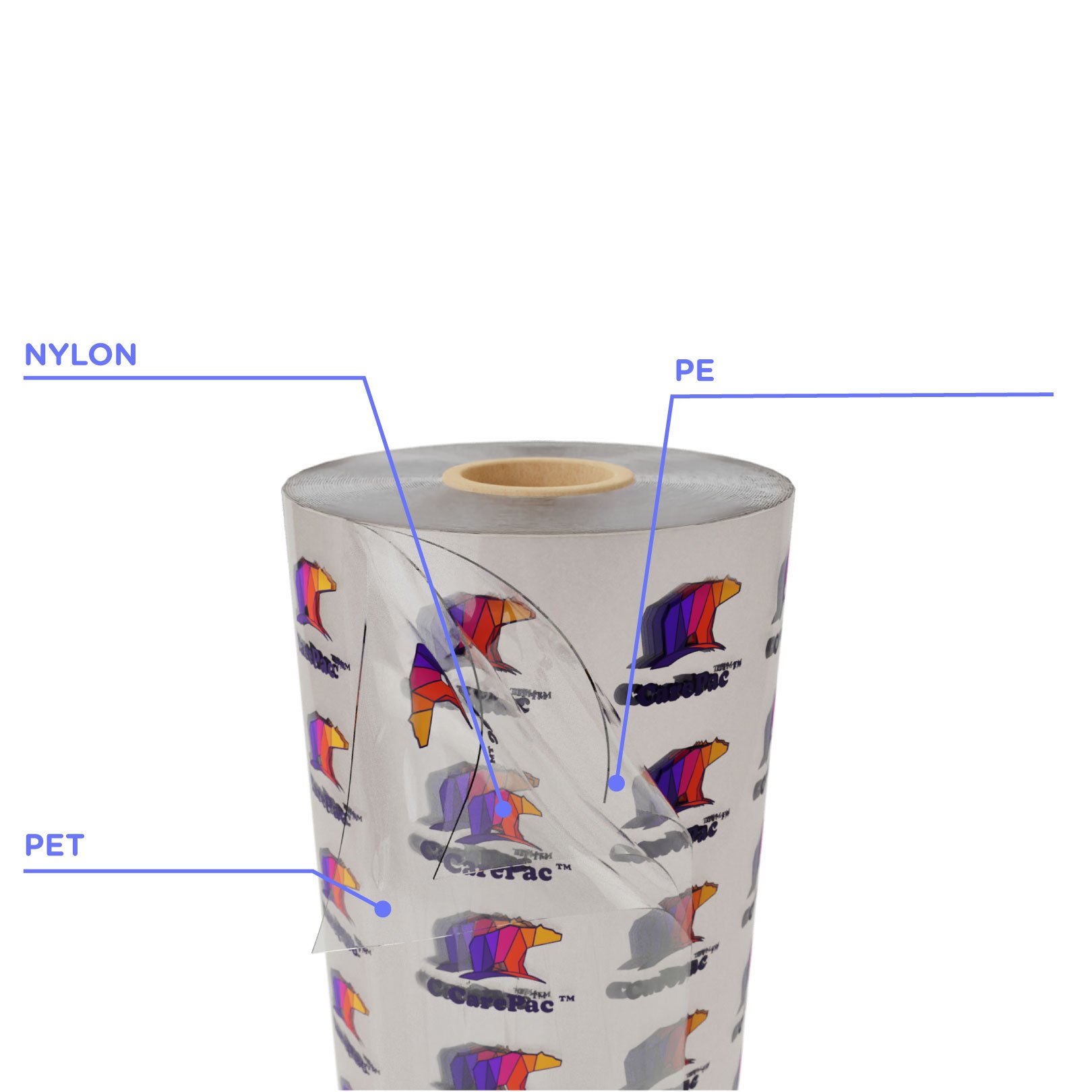

PET/NYLON/PE is a common lamination structure used in flexible packaging. it is the unique combination of three plastic films (the PET a short form of Polyethylene Terephthalate, Nylon also known as PA, and the PE a short form of Polyethylene) that gives our packaging film or bags its unique technical qualities making it ideally suited for a wide range of applications either for domestic or industrial use. The focus of the product is to maintain freshness, extend shelf life and prevent damages to the contents of the package, in a non-rigid form. The unique combination of PET, NYLON, AND PE with coating effect of AL (Aluminum film) to keep oxygen, moisture, and light out, while keeping the product inside fresh and, damage- free.

What Makes Pet/Nylon/Pe Films Or Bags

A Unique Choice For Your Packaging

Nylon (PA) synthesized in the PE/NYLON/PE film/bag is a very tough film with good transparency, good gloss, high tensile strength, good heat resistance, cold resistance, oil resistance. It is excellent in abrasion resistance, organic solvent resistance, and puncture resistance, and is relatively flexible, and has excellent oxygen barrier properties. PET/NYLON/PE typically offers an excellent oxygen barrier and moderate moisture barrier. It's usually stiffer than other PET/PE films and has superior optical qualities. It exhibits high resistance to oil and acidic product contents, whereas PET/PE films are more likely to absorb and become distorted by those substances. PET/NYLON/PE chemical structure is very stable, which means it shows less stretching during the printing and laminating processes. It’s also revered for its excellent thermal stability.

The synthesizing of Nylon or PA material into PET/NYLON/PET FILM greatly impacts the oxygen and moisture barrier, makes for an opaque barrier to light, offers a high-reflective glossy aesthetic, and opens up new packaging application options unlike other PET/PE films or bags that are deficient in oxygen and moisture barrier as well as the glossy aesthetic. In terms of mechanical properties, such as modulus and tensile strength, PET/NYLON/PE typically outperforms PET/PE. At this time, PET/NYLON/PE is well suited for applications requiring a strong film with high tensile properties, scuff resistance, and durability. The synthesizing of Nylon or PA material into PET/NYLON/PET FILM offers an improvement in the moisture barrier.

Packaging Options | Applications |

|---|---|

For Frozen Foods | Resealable laminated bags and stand-up pouches (SUP) for frozen foods |

For Baked Goods | Clear poly bread bags |

For Fresh Produce | Vented and micro-perforated resealable zipper bags for fruits and |

For Meat | Poultry bags, gas flush bags |

For Beverages | Shrink film for case lots |

Other Grocery Items | Completely transparent color and opaque poly bags for dry foods |

For Industrial | Completely transparent color and opaque poly bags for dry foods |

PET, NYLON & PE Structures

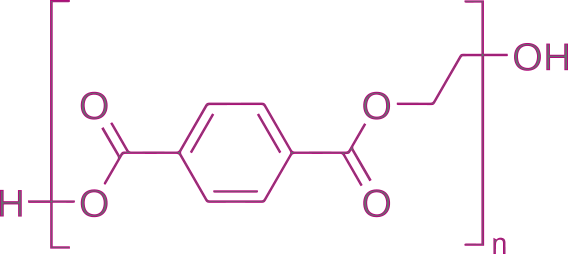

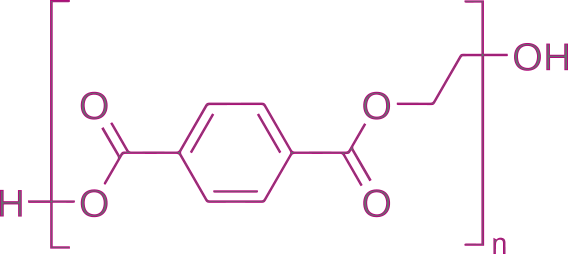

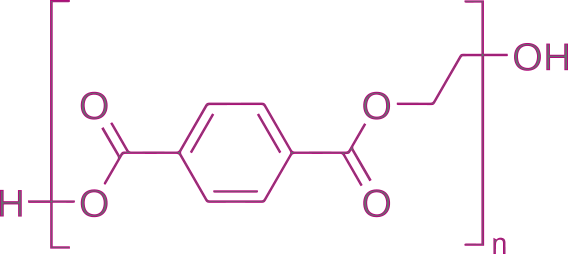

PET (POLYETHYLENE TEREPHTHALATE) or Polyester is a high-performance, crystal clear thermoplastic made from Ethylene Glycol and Dimethyl Terephthalate (DMT). PET is the ideal material for laminating films or bags for quality printing and lamination as well as good choice for high-performance plastic films and sheets. It has a relatively high melting point, which makes it the best choice for applications that demand high temperature sterilization.

Molecular Structure of PET

Molecular Structure of PET

Nylon or Polyamides (PA) is a major high-performance engineering thermoplastics class because of its good balance of properties. Nylon or PA is used because it is a substitute for low – strength metals in applications like automobile engines, and because of its high strength (relative to other plastics), high temperature resilience, and a high chemical compatibility.

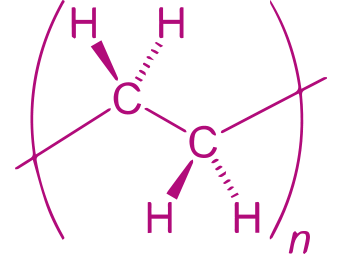

Polyethylene (PE) is known for its durability, lightweight thermoplastic with a varying crystalline structure. Polyethylene is used in applications ranging for films, tubes, plastic parts, laminates, and so on, in numerous packaging options including Beverages, Meat, Fresh Products, Baked Goods, Frozen Foods, For Industrial Packaging & Construction Materials, etc.

Molecular structure of polyethylene in its most stable form

Molecular Structure of PET

AL or Aluminum is a complex material which consists of aluminum foil laminated onto a polyester film base, and it is suited to fields which demand electrical features. It is widely used in high-speed production for flexible packaging films or bags due to its advantages as a swift solution for increasing efficiency. The laminated aluminum film is highly resistant to water and many other chemical components.

PET/Nylon/PE Component

Components | Properties |

|---|---|

PET |

|

Nylon |

|

PE |

|

AL |

|

Comparison of PET/Nylon/PE to other barrier materials

PET/Nylon/PE film is better suited to packaging certain substances over other barrier materials due to its properties. PET/PE film, which is a double layer barrier, has better optical transparency and is lightweight compared to other barrier materials like metals.

It is a transparent material that offers an economical clear barrier. It is also chemically inactive and will not interact with your product in any way.

Technical Specifications

PET/Nylon/PE can be altered in several ways to produce different variations through the use of coatings. It is FDA-approved and possesses a high contact clarity. The example technical specifications below are for a 3.0 mil PET/PE lamination.

Properties | Test Method | Unit of Measure | Typical Value |

|---|---|---|---|

Caliper | mils | 4.0 | |

Yield | sq. In/Lb | 7,700 | |

MVTR | Mocon | gms/100 sq.in. /24 hrs | .8 |

OTR | Mocon | cc/100 sq. in /24 hrs | 4.8 |

Burst | Mullen | PSI | 55 |

Tensile MD | ASTM D-882 | Lbs. at break | 18 |

Tensile XMD | ASTM D-882 | Lbs. at break | 21 |

Tear MD | ASTM 689 | Lbs. at break | 64 |

Tear XMD | ASTM 689 | Lbs. at break | 64 |

Here is a simple table showing the properties of a 3 mil PET/LLDPE laminated film.

Our Packaging Film Or Bags Protects From

- Moisture

- Electrostatic Discharge (ESD)

- Ultraviolet Rays

- Grease

- Oxygen and Air

- Rust and Corrosion

- Dust

- Pests

Customers Specifications

- Stronger polyester or nylon layer helps to prevent sharp edges or angles from puncturing the bag.

- Bags are heat sealable and suitable for vacuum packaging.

- The stapling, folding, or puncturing the static shielding bags eliminates all of the bags' anti-static properties.

- Materials are available for film, bags, rolls, or sheets.

Recycling

PET/NYLON/PE is theoretically recyclable, but the energy required to separate out the plastics from the lamination structure mean that, except for specific jurisdicions, PET/NYLON/PE often is not recycled. PET/NYLON/PE can be commercially recycled by thorough washing and re-melting, or by chemically breaking it down to its component materials to make new PET/NYLON/PE films or bags.

Clear/Silver 3.5×4.5 – 100 Pack

Clear/Silver 3.5×4.5 – 100 Pack