No products in the cart.

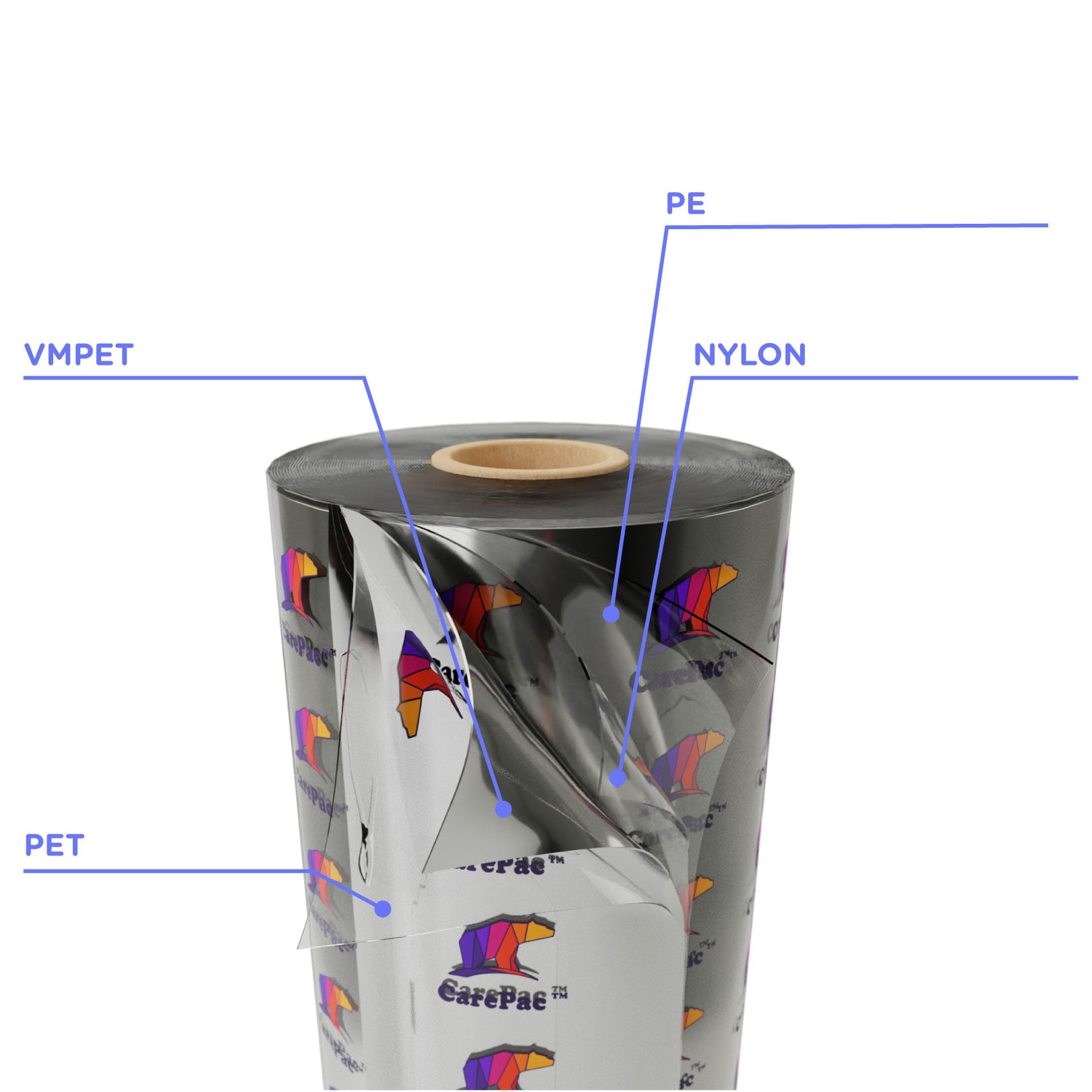

PET VMPET NYLON PE Bags PET/VMPET/NYLON/PE Barrier Bags

What Everyone Ought to Know about PET/VMPET/NYLON/PE

PET/VMPET/NYLON/PE is a lamination film or bag that comes with a four-layer lamination structure consisting of PET, Vapor Metalized Polyethylene Terephthalate, NYLON, and PE. It is our line of Vapor Metalized polyethylene Terephthalate (VMPET) or Mylar films combined with NYLON to offset any form of packaging difficulties.

The versatile nature of our product makes it a unique choice for both industrial or FDA applications as it is free of toxins such as TSE, Sulfur, Phthalates, and BPA. It is specifically designed to maintain the fresh texture of FDA Food Items like dried goods, snacks & chips, Pet Food (cats, birds, and all kinds of dog breeds), and its low thermal permeability rate, as well as the UV resistance, makes it an ideal choice as a pouch for bird seeds, fertilizers, detergents and many more products.

Our lamination film is finely coated with vaporized Aluminum film (AL) to provide an opaque base material for printing while enhancing the barrier properties of the base polymer film.

Why PET/VMPET/NYLON/PE Is The Best Selection Option For VMPET Lamination

The enhancement of PET/NYlON/PE with Vapor Metallization of PET or Mylar provides an higher resistance layer on the film with the same thickness while keeping it flexible for the packaging of your products such as snacks & chips, cookies & candies. Mylar lamination enhances its barrier property against moisture and oxygen while maintaining the freshness of your packaged product, hence, making it the best pouch, and flexible barrier bag option.

VMPET film also provides an opaque surface that improves contrast, color fidelity, and printing quality which invariably attract customers to your product. Your colors will be more vibrant and not have a washed out look that printing on clear base materials can have. Meaning you don't have to worry about choosing one color and receiving a package in a lighter or darker tone.

It gives you the best printing quality as a result of the metalized PET layer. PET/VMPET/PE + NYLON is a great four-layer structure. The synthesized nylon in this material helps with both moisture barrier and strength. Its reinforcement effect on the material is a good choice for powders, granulated items, or heavy bag uses.

Packaging Options | Applications |

|---|---|

For Dried Foods | Resealable laminated bags and stand-up pouches (SUP) for dried foods/goods opaque VMPET films or bags |

Printing / Graphics | The VMPET gives it a crisp appearance making it a perfect option for graphic art design. |

Common Uses | Common examples for this material include protein powder, flours, and feed items (dog food, cat food) Resealable laminated bags and stand-up pouches (SUP) for dried foods/goods opaque VMPET films or bags. Highly effective in preserving bird seeds and generally a Poultry bag, as well as gas flush bags. |

Tea & Coffee | Highly effective in protecting the quality of the tea or coffee due it high-temperature resistant property. Generally best for larger sizes like 1 pound, or 5 pound bags. |

Spout Pouches | Certain liquid spout pouch uses can benefit from this material. |

Drug Packaging | Reduces the permeability of water and oxygen due to its metallic coating, thereby preserving the quality of the product. |

Industrial Packaging Option | An opaque finishing that prevents the effect of UV light and oxidation of packaged fertilizers and detergents Continuous sheeting, liners suited for construction material packaging, and various industrial packaging uses. |

PET/VMPET/NYLON/PE Structures

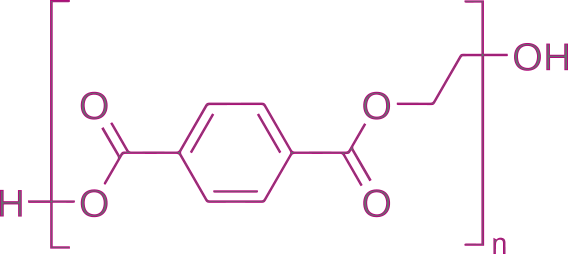

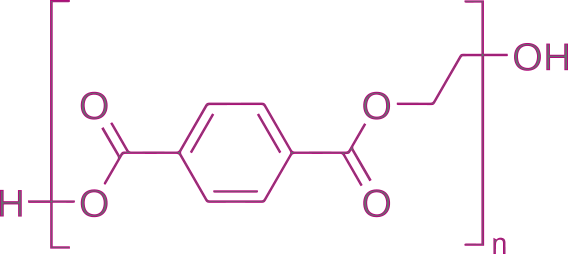

VMPET is the Vapor Metalized form of Polyethylene Terephthalate (PET) or Polyester that gives VMPET/PET/NYLON/PE its unique characteristic as a packaging option. Polyester (PET) is a high-performance, crystal clear thermoplastic made from DMT (Dimethyl Terephthalate) and EG (Ethylene Glycol). VMPET and PET is the ideal material for laminating films or bags for quality printing and lamination as well as a good choice for high-performance plastic films. The two layers provide a glossy surface feature on the lamination layer and thereby providing a water-resistant surface that prevents penetration of water.

Molecular Structure of PET

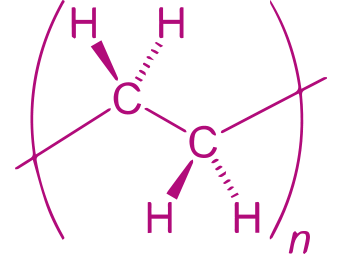

Molecular structure of polyethylene in its most stable form

Polyethylene or PE is a lightweight thermoplastic with a varying crystalline structure while exhibiting excellent durability properties. It is used for domestic and industrial applications ranging for pouches films, tubes, plastic parts, laminates, and so on, in numerous packaging options including Beverages, Meat, snacks &chips Fresh Products, Baked Goods, Frozen Foods dried food, etc.

Nylon or Polyamides (PA) is a major high-performance engineering thermoplastics class because of its good balance of properties.

Nylon or PA is used because it is a substitute for low–strength metals in applications like automobile engines, and because of its high strength (relative to other plastics), high-temperature resilience, and high chemical compatibility.

Molecular Structure of PET

PET/VMPET/NYLON/PE Component

Components | Properties |

|---|---|

VMPET | High resistance to moisture and oxygen permeability. |

PET | Excellent dimensional stability |

Nylon | Good abrasion and wear resistance |

PE | Excellent electrical insulating properties |

AL | Good impact strength, even at low temperature, provides a exceptional barrier to oxygen and moisture. |

Comparison of PET/VMPET/NYLON/PE to other barrier materials

PET/VMPET/NYLON/PE film is better suited to packaging certain substances over other barrier materials due to its properties. PET/PE film, which is a double layer barrier, has better optical transparency and is lightweight compared to other barrier materials like metals.

It is a transparent material that offers an economical clear barrier. It is also chemically inactive and will not interact with your product in any way.

Technical Specifications

PET/PE can be altered in several ways to produce different variations through the use of coatings. It is FDA-approved and possesses a high contact clarity. The example technical specifications below are for a 3.0 mil PET/PE lamination.

Properties | Test Method | Unit of Measure | Typical Value |

|---|---|---|---|

Caliper | mils | 3.0 | |

Yield | sq. In/Lb | 8,564 | |

MVTR | Mocon | gms/100 sq.in. /24 hrs | .33 |

OTR | ASTM-1434-66 | cc/100 sq. in /24 hrs | 7.3 |

Haze | Mullen | PSI | 47 |

Tensile MD | ASTM D-882 | Lbs. at break | 19 |

Tensile XMD | ASTM D-882 | Lbs. at break | 22 |

Tear MD | ASTM 689 | Lbs. at break | 48 |

Tear XMD | ASTM 689 | Lbs. at break | 48 |

Puncture | Fed. TM 2065 | Lbs | 12 |

Here is a simple table showing the properties of a 3 mil PET/LLDPE laminated film.

Our Packaging Film Or Bags Protects From

- Moisture Vapor and Water

- Electrostatic Discharge (ESD*)

- Dust

- Grease/Oil

- Oxygen and Air

- Rust and Corrosion

- UV

- Pests and Rodents

Customer Specification

- The enhanced Nylon layer helps to prevent sharp edges or angles from puncturing the bag.

- Materials are available for pouches, film, bags, rolls, or sheets.

- A thermal and UV resistant pouch, film, or bags for bird seeds, fertilizer, and detergent.