No products in the cart.

Pouch Packaging Finish

So you've done your market research, come up with a great idea for a product, and designed some eye-catching packaging. Now what? Fittingly, if you're packaging your product in a pouch, one of the last steps you'll need to check off your list is picking a finish.

However, selecting a finish requires more than just going with your gut — certain pouch finishes are better for certain products or locations, and making the wrong decision can have dire consequences.

Don't worry: there's a great finish out there for your product. All you need to do is find it.

If you don't know where to start when it comes to packaging finishes, read on to learn all about the different pouch finishing types available today and what their ideal applications are. or watch our handy dandy video covering finishes!

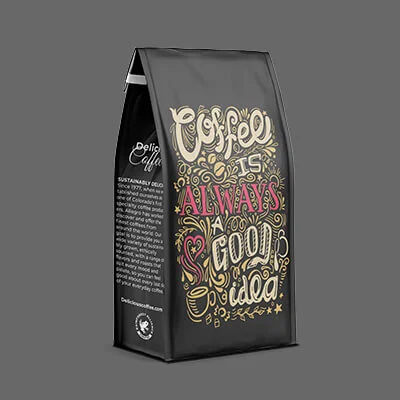

Glossy Finish

Few things are more unforgettable than a beautifully crafted package with a glossy finish. Not only do humans naturally respond enthusiastically to shiny things, making it likely that your pouch will attract plenty of attention, but a gloss finish can also be used strategically to highlight key logos, words, or images on your packaging. In addition to its high shelf impact, packages with a gloss finish can handle scratches and smudges, as well as dust and dirt, to keep them looking great over time. Finally, a gloss finish can be used to create stunning, vibrant colors that draw consumers in. Read more here.

Going for a glossy finish is perfect for anyone who's not as concerned about projecting an all-natural image as they are about catching consumers' eyes and hooking them with bold colors and artwork. For instance, a candy manufacturer who wants to express high-energy fun with their packaging might benefit from the durability and vibrancy of a glossy finish.

Gloss is the default finish for barrier pouches for a reason: it has a gorgeous aesthetic, is ultra-durable, and allows clear windows so your customer can easily see what’s inside. Learn more about this elegant, stylish finish and how it compares to matte packaging by visiting our glossy packaging page.

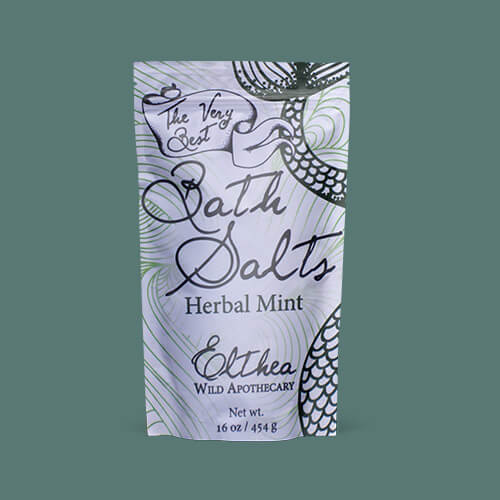

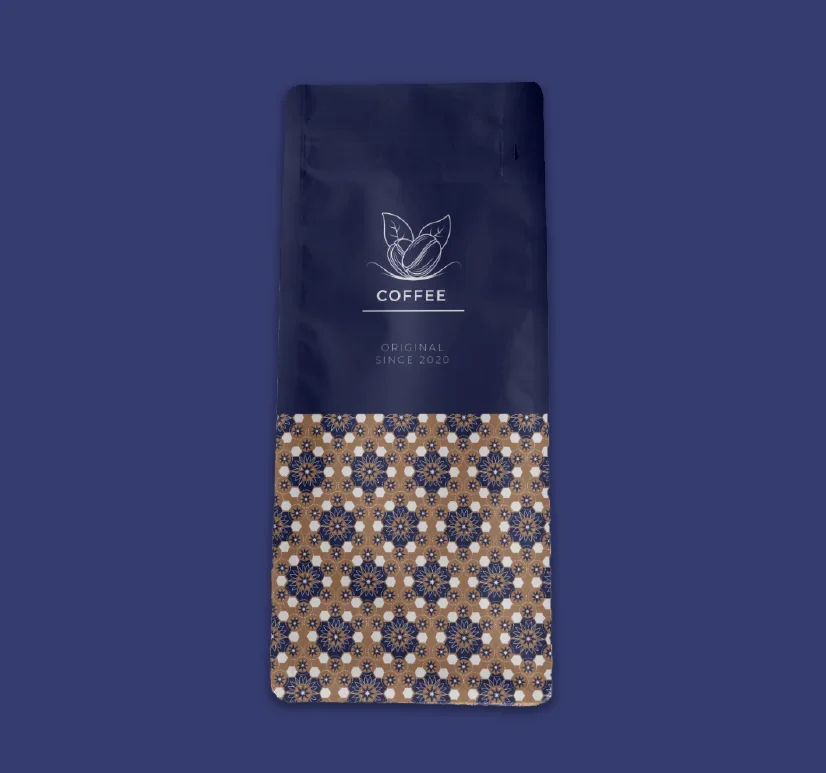

Matte Finish

Matte is currently one of the most trendy options for packaging finishing today. Its sophisticated look and texture make it perfect for adding a sleek and modern edge to a wide variety of products. More specifically, a matte finish has several key qualities that make it an ideal choice for packaging specific products, such as:

A matte finish stands out. In locations like supermarkets, glossy and shiny packages are the norm, which means that a matte finish stands out to consumers. And with most supermarket consumers spending as little as 3 to 5 seconds making a decision about what product to buy, being able to stand out is absolutely crucial for the success of your product.

Its contents are perceived to be more natural. A recent study demonstrated that packaged food products were perceived to be more natural when they were in matte packages than when they were in glossy packages. These customers also expected the more natural food to taste better and were more likely to buy it.

It's easier to read. In contrast to shiny, glossy packaging, matte packaging reflects less light on the consumer and is thus easier to read. In an environment where every second counts when it comes to convincing a consumer to buy your product, making your product's packaging as easy to read as possible is a no-brainer.

While matte may be trendy, it's not very flashy and, therefore, isn't a perfect fit for every product. However, if you're packaging all-natural food — like coffee, granola, or jerky — that you want to stand out on a crowded supermarket shelf, a matte finish can be a great way to help your product appeal to consumers looking for a natural, eco-friendly choice. Check out all our matte finish options.

There are three primary types of matte finishes that we offer for our packaging: matte lamination, matt varnish coating, and soft-touch matte coating. You can learn more about these finishes, plus explore our options, like spot matte or a matte frosted effect, by visiting our matte packaging page.

Soft Touch Finish

If your brand is all about luxury, soft touch finishing may just be the perfect choice for your product. Soft touch finishing is used to give products a silky-smooth look and soft, velvety feel that will register with your customers as high-end signifiers. Additionally, because the surface of a soft-touch package has a minimal sheen and appears to be almost matte from a distance, it has all of the benefits associated with a matte finish, such as a sophisticated appearance and all-natural essence.

When it comes to determining what products benefit from a soft touch finish, the sky's the limit. The main criterion is that most soft-touch packaging comprises high-end, luxury products, making it the perfect choice for upscale vendors in the cannabis, cosmetics, dried fruit, or tea industries. With its primary drawback being its higher cost, soft touch finishing is a great choice for products for which you want to communicate a sense of luxury and indulgence to their consumers. Soft touch is available as a coating or a lamination.

Soft touch packaging is all but guaranteed to elevate your product above the competition by giving it the ultimate feel of luxury. We offer both soft-touch coating and soft-touch lamination, putting the power in your hands. To learn more about our line of flexible barrier pouches with elegant and soft finishing, visit our soft touch packaging page.

Spot UV Finish

Spot UV printing is a great way to add a touch of upscale sophistication to your packaging. Because UV printing uses ultraviolet (UV) light to cure varnish in specific areas, it not only produces vibrant, high-sheen packaging but also can be used to target only specific spots or areas. By mixing and matching a spot UV finish with, say, a matte finish, you can end up with a premium, high-end blend of textures. Additionally, the glossy sections of the packaging will have all the protection of a high-gloss finish — meaning that they'll be able to resist scratching and avoid damage due to moisture.

Because of its high-end look, a spot UV finish is perfect for high-end products. Luxury cosmetics and cannabis companies can attract a more upscale clientele if their packaging boasts a spot UV finish, and artisanal candy, coffee & tea, and other food companies can stand out by using a finish that suggests their products are high-quality and bespoke. If you're looking for a finish for your products' pouch packaging that is both eye-catching and luxurious, a spot UV finish might be the right choice for you.

Whether you opt for a spot gloss wallpaper pattern, a spot gloss logo, or spot gloss on images, the real power of this type of finish combination is in its ability to highlight important graphics and make them stand out from the rest of the bag. To learn more about spot UV printing and how it can differentiate your products on the shelf, visit our spot UV finishes page.

Metallic Finish

Metalization is an advanced printing technique where very specific areas of your bag or pouch have a metalized effect applied to them. Using metallic effects on your bag is a great way to showcase a specific design element of your bag, and provides a striking visual effect that is sure to catch the eye of your customers as they browse the shelves at the store. Whether you sell dog treats, cookies, cosmetics, or cannabis, metalized bags and pouches will be sure to make your customers curious about what’s inside.

This type of finish is a great way to emphasize a certain element of your bag (e.g.: your logo, a certification badge, watermarks, or awards), and any of the colors can be metalized. Common metalized colors include silver, gold, and rose cold, but any color of the rainbow can be metalized during our in-depth design and customization process.

Currently, CarePac offers several different methods of pouch metallization, including embossed foil, relief metallization, and DMET metallization. The traditional form of metallization is embossed foil, which is what most consumers are most familiar with. To learn more about embossed foil, relief metallization, DMET metallization, and the rest of our metallic finish offerings, visit our metallic finish page.

Holographic Finish

A holographic finish actually creates a faux holographic-like effect that will give your pouch a shimmering iridescent quality. Holographic or iridescent finishes help create beautiful and eye-catching designs that will leave a lasting impression on your customers. With our unique design and customization process, it has never been easier to add holographic elements to your product packaging.

By incorporating holographic elements into your packaging, you can take your packaging to the next level. Depending on the base material you use for your bag, bags with holographic finishes can be recyclable and biodegradable, and some companies use holographic finishes for anti-counterfeit purposes. Regardless of your reason for using a holographic finish, or if you make the entire bag holographic or just a specific part, it’s sure to set your product apart from the other products on the shelves.

To learn more about our holographic finishes and how to apply holographic elements in your design files, visit our holographic finish page.

Contact CarePac Today

At CarePac, we have all the expertise and experience we need to help you select and apply the right finish for your packaging. We'll take into account your specific needs as well as your budget to help you decide on a finish that helps your product stand out in all the right ways.

We're always here to help, and our team is always available by phone to answer any questions you might have. If you're ready to get started, visit us online to get an quick quote today. We're excited to help make your packaging dreams a reality!