No products in the cart.

Rotogravure Printed Pouches | Printed Pouches & Rotogravure Printing

Rotogravure printed pouches are pouches that are printed via a intaglio printing process. This Gravure printing process is a complex one and involves meticulously laser engraving images directly into copper cylinders, which are then inserted into a commercial rotogravure printing machine. Once in the machine, these custom cylinders then add ink directly to printed pouches. The ink color being laid down by each must be calibrated or “registered” to ensure the best print outcome.

Roto presses can accommodate up to eight to ten colors and, since each cylinder is custom to your project it’s a better option for higher-volume SKUs (5,000+), and scaling customers with repeat runs. Though a 5,000 MOQ may seem high, it used to be much higher -- advances in technology have brought down the MOQ. Yes, the lead times are longer and the MOQ is higher, but, for one, the color matching properties and per-unit cost of rotogravure printed pouches simply can’t be beat. Rotogravure is a good one for scaling businesses, who want to take advantages of reduced unit cost as they order more bags.

CarePac Rotogravure Printed Products

At CarePac, we pride ourselves on our extensive offerings, including flexographic printing and our printed pouches. From our bag features and material and finish options, we love customization and ensuring that the bag you design has all the features you want. Whether you custom order your roto printed bags with all the bells and whistles or opt for something more streamlined, here are some of the key benefits of working with CarePac.

Custom flexographic printing for scaling businesses

Rotogravure printing is ideal for larger orders where color matching is key -- spot or PMS colors are actually hand-mixed for an exact match in the amount needed to complete the full run, resulting in little to no color variance between products. Unlike other forms of pouch printing, the colors can even be saved for the next run!

Lowest Per-Unit Cost

Generally speaking, rotogravure will almost always yield the lowest per-unit cost on production run and pouches (5,000+ pouches). As such, rotogravure printing is suitable for all kinds of bag applications (from printed standup zipper and beyond!) and for almost any industry. The vast majority of the plastic bags you’ve seen in big-box stores are printed via this process, including:

It’s worth noting that the best applications for roto printing aren’t based on industry, rather on MOQ. If you have a large printing order and desire color matching properties across your different orders, rotogravure printing is, simply put, the best choice.

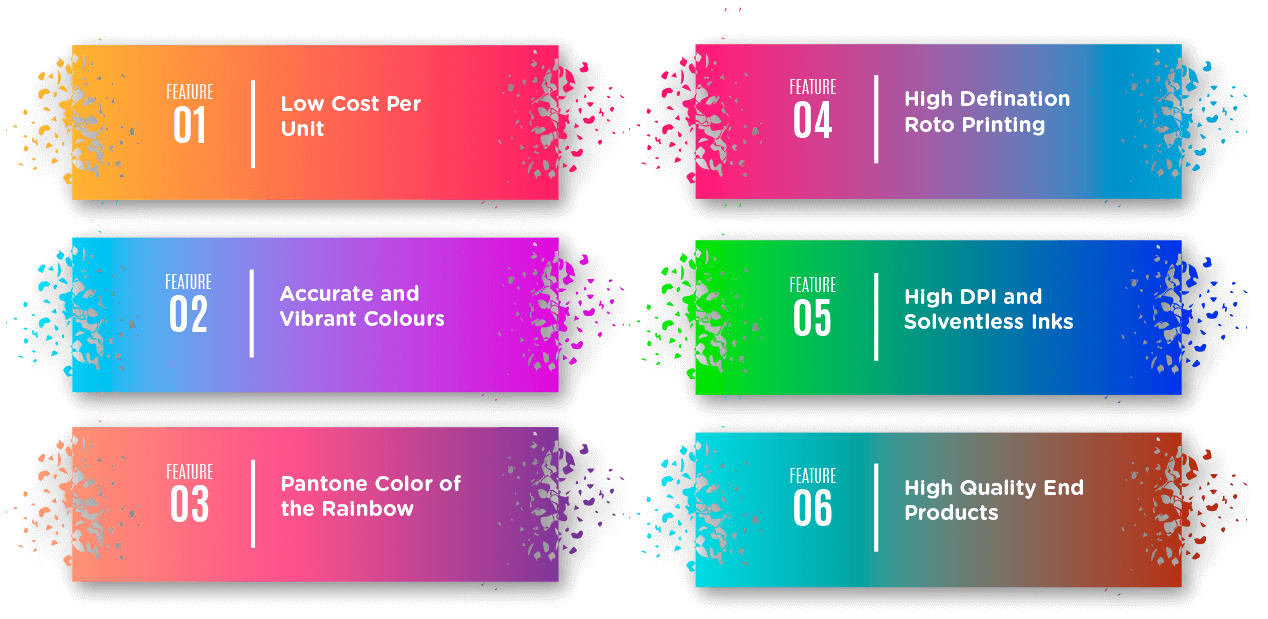

Key Features of Rotogravure

There are a few benefits that are specific to rotogravure printing, including a low cost per unit. Above we mentioned that the initial costs are higher than other methods of printing, but for large volume or repeat orders the overall cost per unit ends up being lower. With roto printing, the colors are both more accurate and more vibrant. We can match any (Pantone) color of the rainbow! Roto printing is high definition, with high DPI counts, and uses solventless inks for a truly high-quality end product.

Base Materials for Pouches

In regards to materials, we’re able to print using a wide variety of materials, including PET, MOPP, BOPP, and some compostables, like PLA and NatureFlex. Here are some of the most common materials and plastic films we use for our roto printing projects:

Looking for a material that isn’t on this list? Browse all our materials, or reach out to us for more information. Our helpful customer support team is ready to answer any and all of your questions about our stand up pouches.

Finish Options

This is the area where rotogravure printing really shines! Roto printing is compatible with all available finish options, and is even compatible with 2+ finish options on one single pouch. CarePac has a variety of finishes to choose from, including soft touch, holographic, and metalization. For a full breakdown of the finish options offered through CarePac, please visit our finishes page for more information.

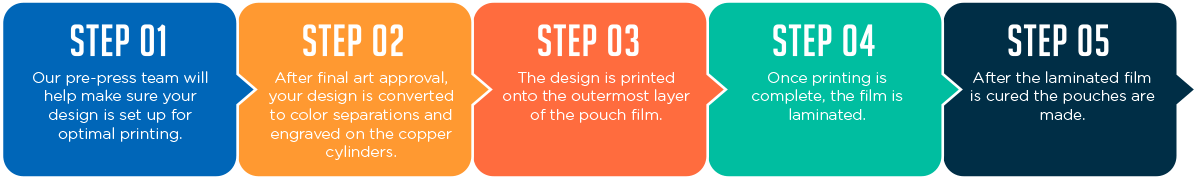

CarePac’s Rotogravure Printing Process for Pouches

If CarePac is one thing, it’s consistent! This is why our rotogravure printing process is similar to our printing process for all our other bags. Here’s a look at what our rotogravure printing customers can expect when they partner with CarePac for their printing needs:

As mentioned, we’ll hang onto your colors for the next run! We make it super easy to order (and re-order…and re-order…) because we know that packaging is the last thing on your mind. We’re happy to handle the process from start to finish, but also love collaborating with our customers on creating the bag of their dreams.

Digital Printing vs Rotogravure Printing

Rotogravure printing is preferred for its color matching properties and low cost per-unit benefits. The low CPU does come with a caveat though -- there’s generally a 5,000 MOQ. If you’re looking for a commercial print job and have lots to print, rotogravure is the best choice for you. The more you print, the cheaper the price per piece becomes. With rotogravure printing, you’ll also have access to special custom inks, a larger variety of material structure types and custom finishes, and the highest possible printing quality. Simply put, roto printing = greater attention to detail and color vibrancy.

Of course, digital printing does have its uses, which we explain in-depth on our digital printing page. With digital printing, there are no printing plates costs and you can print only the amount you need (low MOQs!). Ultimately, digital printing is the more accessible option.

Digitally Printed Pouches

Digital printing is the process of printing digital-based images directly onto your package. Artwork is separated into five ink colors: white, cyan, magenta, yellow and black (CMYK+W) This type of printing is best for small runs, or where you have a lot of different designs. Some advanced coatings, and techniques (Spot UV, Spot Matte) are not possible with digital printing.

Pros:

Cons:

Rotogravure Printed Pouches

Plate printing is commercial printing where the design of your bag is separated into multiple color plates. Plate printing yields the lowest per unit costs available. Brands you see in Walmart, Target, and so forth generally use plate printing. Most jobs can be completed with three to six plates. Use of metallic color may require additional plates. Use up to 10 colors.

Pros:

Cons:

Digital vs. Rotogravure Printing

Price Comparison

10,000 Digital Printed

$2,500

25 cents per bag!

10,000 Plate Printed

$1,450

14.5 cents per bag!

*CarePac offers incredible pricing on customer printed barrier bags. Our plate and digital print is of the highest quality. Please note that depending on your choice of material, configuration, quality, and other factors your price may be more or less. Contact our office to get a quote for project today!

The CarePac Guarantee- Contact Us Today!

CarePac focuses exclusively on custom flexographic packaging for a variety of industries, from cannabis wholesalers to food and beverage distributors. We have exceptional customer service reps ("care" is in our name after all!) who are committed to making sure your roto printing order is completed to perfection. With our CareDesign® process you can rest assured that your custom standup pouches will be done right, no matter what.

From nailing down the right colors to making sure the logo is in the right place, we understand you put a lot of time into perfecting the look and feel of your product packaging. With vivid colors, a wide material selection, and low cost per unit, our rotogravure printing is just what you need to make your project a reality. Ready to experience the CarePac difference? Contact us and get a quote to get started today!